There are a few things I'd like to do in this thread

- document my soap making process

- document process changes and upgrades to equipment

- detail common problems when making soap

- answer any soap making questions

- eventually let everyone know when and where product can be purchased

Basically everything to do with soap.

I'm not concerned about telling somebody how to make a product that I'm selling either. There are a few reasons for this: Some people won't be able to receive such a product overseas, or it wouldn't be feasible to ship. I'm not so petty to think that trying to conceal information somehow results in "job security". The soap making process is already quite well documented. Finally, I didn't start making soap to make money with, I started because of the memes, but also to have a product to better prepare myself for economic collapse.

I wish to share this with you guys so (you) too can better prepare yourself for whatever is coming.

Lets start with the boring stuff, like what is soap?

I would define soap as a surfactant. A surfactant is a molecule that will bind to water, oil, and particles.

The US legal definition is 'soap made from natural ingredients'. Synthetic soap is often sold as 'beauty bars' or 'body wash' instead of soap, because they are not made with natural ingredients.

Most modern engine and transmission oils, and heavy grease used for equipment will contain detergents. Don't let the word detergent mislead you, it means the same thing as surfacant.

Lye harvested for soap making in ages past is called potash. The potash lye soap making process is a fair bit more involved, and the chemical reactions are a bit different. https://classicbells.com/soap/woodAshLye.asp

Potash soap has been made for a very, very long time. If one of you decides to try this out, please let us know how it goes!

"modern" naturally made soap uses either potassium hydroxide or sodium hydroxide for the lye. Sodium hydroxide is used for making liquid soaps, sodium hydroxide for solid soap bars.

The easiest way to get sodium hydroxide is from a hardware store selling containers of "pure lye" drain unclogger in the plumbing section. For example https://www.homedepot.com/p/Instant-Power-Crystal-Lye-Drain-Cleaner-1650/204374017

Soap made from natural ingredients is a very sloppy chemical reaction. There are untold numbers of different chemicals and compounds found naturally in any given type of oil. Most of those oils will react with the lye to make some rather complex reactions that result in "soap". It is not uncommon for the soap to change color as it cures for this reason.

Oils are typically mixed and matched to make a nice bar of soap, as no single oil has a good mix of the fatty acids necessary for a good bar of soap.

When making your first batch of soap:

Start with solid bars of soap, instead of trying to make liquid soap. Liquid soap is much pickier about what kind of oils you use.

Use an existing recipe for your first batch, then try to make soap using as much local products as possible. When economic collapse happens, getting those foreign oils will be much more difficult or impossible.

Start with a 2:1 water:lye ratio. If your recipe calls for 12 ounces of lye, use 24 ounces of distilled water. Ignore however much water the recipe calls for.

When building your own recipe, or modifying an existing one, use the following two web pages:

http://soapcalc.net/calc/SoapCalcWP.asp

https://classicbells.com/soap/soapCalcNumbers.asp

And when in doubt, ask in here.

This first post is just a boring autistic dump on chunks of important or related information. I'll post a lot more (actual making) soap stuff when I get the chance. I think this is a pretty good start though.

Be sure to ask whatever in here about anything related. Over the last year I've been pretty autistically going over how most people make soap, refining my own process, and doing fairly deep-diving research on the topic and general chemistry.

/ub/ - Überhengst

Becoming better

53 replies and 27 files omitted.

>>5110

Laser printers should be able to print graytones (at least mine can). But could be you have one of those thermal label printers.

Laser printers should be able to print graytones (at least mine can). But could be you have one of those thermal label printers.

>>5111

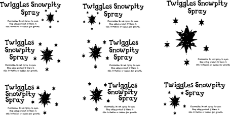

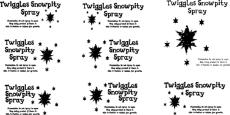

Alright, I tweaked some things and tried it out.

It appears it will "do grayscale" on the most technical level, but its dithering which laser printers are traditionally not very good at.

Took a picture to show what I mean.

I guess it would be alright for a label.

>>5107

As near as I can tell, for everyone I ask the arrangement of the words and which version they like is a pretty mixed bag.

I'm not getting any obvious trends (yet)

Maybe it is because everyone is busy thinking about throwing money at me for the product rather than actually analyzing things. I guess that would be a good problem.

Alright, I tweaked some things and tried it out.

It appears it will "do grayscale" on the most technical level, but its dithering which laser printers are traditionally not very good at.

Took a picture to show what I mean.

I guess it would be alright for a label.

>>5107

As near as I can tell, for everyone I ask the arrangement of the words and which version they like is a pretty mixed bag.

I'm not getting any obvious trends (yet)

Maybe it is because everyone is busy thinking about throwing money at me for the product rather than actually analyzing things. I guess that would be a good problem.

>>5112

I see what you mean. Have you tried to play with the grayscale level to see if there is a gray level sweetspot your printer likes?

But also remember making it gray might not be the best route artistically so don't take my suggestion as gospel. My artistic skills or aesthetic knowledge is not what you would call good. Only reason my first thought was gray and center was because it felt a bit unbalanced/"left heavy" (or what to call it) so I thought centering it and making it gray it would balance the label overall and also get the "out of the way" of the text.

Made a few more mockups in only black and white, but not sure if they are any better or just making it worse. But added so you have more variations to play with and think of. Added the vector so you can easily move objects around and resize in InkScape.

Logos are hard and I don't really know what to suggest and recommend. Hopefully more people will give their two cents and likely have more knowledgeable feedback than what I can give (and gave).

I see what you mean. Have you tried to play with the grayscale level to see if there is a gray level sweetspot your printer likes?

But also remember making it gray might not be the best route artistically so don't take my suggestion as gospel. My artistic skills or aesthetic knowledge is not what you would call good. Only reason my first thought was gray and center was because it felt a bit unbalanced/"left heavy" (or what to call it) so I thought centering it and making it gray it would balance the label overall and also get the "out of the way" of the text.

Made a few more mockups in only black and white, but not sure if they are any better or just making it worse. But added so you have more variations to play with and think of. Added the vector so you can easily move objects around and resize in InkScape.

Logos are hard and I don't really know what to suggest and recommend. Hopefully more people will give their two cents and likely have more knowledgeable feedback than what I can give (and gave).

>>5114

The other thing to note is that cutiemarks are not "balanced" by themselves either. Luna and Rainbow Dash for example. I'll see how they look when I get around to it, hopefully soon.

Need to decide on where to get website hosting, build the website that can process payments, and what kind of URL I want to use.

Yesterday after playing around with label sizes (cut out some 3x5 cards) to see how the bottles would look with a sticker on it, I ordered 2"x2" stickers along with all the basics for packaging and shipping.

Realistically, the dithering isn't that bad, I think its growing on me. There is another thing I could try too: Give the text a white background, maybe with a blur so that there is only a little bit of dithering for the butt branding where the text and butt branding overlap.

Thanks for the help, anon. Certainly more than I've gotten anywhere else.

The other thing to note is that cutiemarks are not "balanced" by themselves either. Luna and Rainbow Dash for example. I'll see how they look when I get around to it, hopefully soon.

Need to decide on where to get website hosting, build the website that can process payments, and what kind of URL I want to use.

Yesterday after playing around with label sizes (cut out some 3x5 cards) to see how the bottles would look with a sticker on it, I ordered 2"x2" stickers along with all the basics for packaging and shipping.

Realistically, the dithering isn't that bad, I think its growing on me. There is another thing I could try too: Give the text a white background, maybe with a blur so that there is only a little bit of dithering for the butt branding where the text and butt branding overlap.

Thanks for the help, anon. Certainly more than I've gotten anywhere else.

>>5118

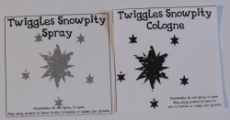

I don't really like the outline thing. Also I am trying out essence instead of spray.

I think I like spray with the white background blur the best, #2

Resized the cutiemark a bit so its slightly smaller. I think I like it. Should be good for all the other butt brandings too.

I don't really like the outline thing. Also I am trying out essence instead of spray.

I think I like spray with the white background blur the best, #2

Resized the cutiemark a bit so its slightly smaller. I think I like it. Should be good for all the other butt brandings too.

Ah, a Squirt of Snowpity? A Snowpity Splash? A Sniff of Snowpity? ASoup of Snowpity? Snowpity Mark? Rendered Snowpity? Snowpity Quantized?

>>5129

Looks really good. Just though of one thing, is there any requirements of listing ingredients (in case you need to make a back label)?

Looks really good. Just though of one thing, is there any requirements of listing ingredients (in case you need to make a back label)?

>>5130

No requirements. Not for skin care products anyway, like soap, perfume, eye shadow, and similar.

Its literally just two ingredients though

Fragrance oil (snowpity)

food grade alcohol

No requirements. Not for skin care products anyway, like soap, perfume, eye shadow, and similar.

Its literally just two ingredients though

Fragrance oil (snowpity)

food grade alcohol

>>5134

iunno if the fragrance oil is safe to consume. Though, I'd imagine it would be safer than a lot of the processed foods made these days.

iunno if the fragrance oil is safe to consume. Though, I'd imagine it would be safer than a lot of the processed foods made these days.

>>5142

It's not something you can own, see, or feel. It's something beautiful tied to the direct essence of a mare and her kind mares spirits. Lurk moar.

https://snowpity.com/

It's not something you can own, see, or feel. It's something beautiful tied to the direct essence of a mare and her kind mares spirits. Lurk moar.

https://snowpity.com/

1648331879.png (193.4 KB, 894x894, okie_dokie_loki__by_johansrobot-d9tuk7d.png)

>>5144

>implying I didnt do several websearches prior to asking, including that specific site

I was hoping for something a little less vacuous, but okay

>implying I didnt do several websearches prior to asking, including that specific site

I was hoping for something a little less vacuous, but okay

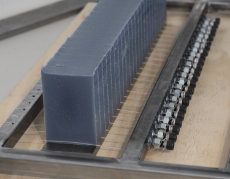

Here is the first use of my heat-shrink equipment. Seems to work well.

Need to make labels for the soap, but at least I can use normal paper and slip it inside the heat-shrink bag. Though, I don't think the pone soap needs a label really. Dunno, maybe.

Need to make labels for the soap, but at least I can use normal paper and slip it inside the heat-shrink bag. Though, I don't think the pone soap needs a label really. Dunno, maybe.

>>5150

Do you mean the soap bars? or the plastic?

Still working on dye, that was my first batch made with my soap mold. Also messed up with the thermal profile, so the middle is caved in along the top for the whole batch as detailed in earlier postings.

The plastic is just being plastic. There are holes in the plastic for a reason... need some ventilation to let moisture escape and for a sniffy place.

Do you mean the soap bars? or the plastic?

Still working on dye, that was my first batch made with my soap mold. Also messed up with the thermal profile, so the middle is caved in along the top for the whole batch as detailed in earlier postings.

The plastic is just being plastic. There are holes in the plastic for a reason... need some ventilation to let moisture escape and for a sniffy place.

Here is the first of the soap labels

To be printed on 2"x3" yellow paper. I just made the background yellow to more or less get an idea how it's going to look.

(kek, accidentally uploaded the SVG, have a PNG instead)

To be printed on 2"x3" yellow paper. I just made the background yellow to more or less get an idea how it's going to look.

(kek, accidentally uploaded the SVG, have a PNG instead)

>>6191

Not at all, just extremely busy. Started attempting to soap mill for my most recent soap research project.

Got all the labels done and a website launched barely in time (literally the day it started) for the 4chin /mlp/con and had a 1/2 hour ramble - now I'm recording for /mare/con and will start video editing soon.

Discovered its the lard I'm using that is screwing up my soap, so I need to find a better source for lard/tallow. I got some fat to render from a local BBQ place, but I need a lot more in general, still looking around. Mayhaps local butcher shops.

Made my first batch of soap using Christmas-themed fragrance, which is nice. Until I get soap milling working correctly, it takes a month or more to cure a bar of soap, so I gotta start making soap for Christmas right now.

Over the weekend installed arch linux on both desktop and laptop, going through and setting up various things and importing all the backups I made.

Got a new job a bit ago, mostly done adjusting to that now.

Can't really attach quality images right now, since I'm still importing shit from backups, but you can see some lower resolution ones on pone.social.

Have a website (no international shipping set up yet) https://snowpity.shop

Another place I started posting at: https://pone.social/@soapone

Even have a secret soap project I'm making that is going to be featured in an event I can't talk about until there is an official announcement.

One of the main reasons I haven't posted here yet is because I haven't had a chance to properly document soap making processes... which I'm still adjusting slightly as I go.

Stay clean everyone, I'm working on this stuff as much as I can. I love you all so much.

[Read more] Not at all, just extremely busy. Started attempting to soap mill for my most recent soap research project.

Got all the labels done and a website launched barely in time (literally the day it started) for the 4chin /mlp/con and had a 1/2 hour ramble - now I'm recording for /mare/con and will start video editing soon.

Discovered its the lard I'm using that is screwing up my soap, so I need to find a better source for lard/tallow. I got some fat to render from a local BBQ place, but I need a lot more in general, still looking around. Mayhaps local butcher shops.

Made my first batch of soap using Christmas-themed fragrance, which is nice. Until I get soap milling working correctly, it takes a month or more to cure a bar of soap, so I gotta start making soap for Christmas right now.

Over the weekend installed arch linux on both desktop and laptop, going through and setting up various things and importing all the backups I made.

Got a new job a bit ago, mostly done adjusting to that now.

Can't really attach quality images right now, since I'm still importing shit from backups, but you can see some lower resolution ones on pone.social.

Have a website (no international shipping set up yet) https://snowpity.shop

Another place I started posting at: https://pone.social/@soapone

Even have a secret soap project I'm making that is going to be featured in an event I can't talk about until there is an official announcement.

One of the main reasons I haven't posted here yet is because I haven't had a chance to properly document soap making processes... which I'm still adjusting slightly as I go.

Stay clean everyone, I'm working on this stuff as much as I can. I love you all so much.

>>6194

Awesome. It's good to see that you're still around and making progress. Congrats, have a tiny essence mare that I edited with my autism 4u.

Awesome. It's good to see that you're still around and making progress. Congrats, have a tiny essence mare that I edited with my autism 4u.

Alright, finally time for a big soap update of the last... oh dear, has it really been half a year?

First I'd like to thank the anons here who helped come up with the soap label ideas by the power of shitposting and autism.

>>6575 Mix jojoba oil and castor oil together. This is the best thing to use on skin or hair to keep it soft, supple, and pliable. This is what I sell as "Aloe and Lotus Conditioning Oil", there really isn't anything better for skin use than both of those oils. They don't mix though, so you will need to shake it before every use.

>>6195 Thanks, I really like it, even though I haven't even seen that episode (stopped watching around mid-season 7)

>>6191 Basically I took a break from a lot of things. Still kept doing the soap stuff but cut back on a lot of other things and relaxed a bit over the last month.

Hoooo boy lots of updates to cover.

Lets start with dye, where I left off at.

All of the soap bars require a little bit of white dye, generally one or two teaspoons for a batch. Sometimes less and sometimes more (more for Rarity, less for Celestia) because after I changed around temps and how much water I use, the natural color of the soap is pinkish, fair skin tone sort of color.

I mix/blend the dye with a portion of the oil in a blender first, and add that to the mixing bowl just before adding the lye to start the soap making process.

Changed the amount of water:lye ratio to roughly 1.75:1 at 2:1 there is just enough water that the soap just starts to leave a white ashy top surface. While harmless, it does mess with color and presentation a bit. Soda ash forms from the sodium hydroxide reacting with the carbon dioxide in the atmosphere. I think I mentioned this in previous posts and how it forms depends on how much water you use and what temp the soap is made at.

Alright, some pictures to highlight the progress, starting with the first image

Designed and welded up a soap cutter to use with my steel soap mold. At first I used some wire, but that didn't work very well. After thinking about it for a bit, decided to use heavy duty fishing line. This has worked quite well. Overall quite pleased with it.

Shaving soap! Also toothbrush soap to brush teeth with. The design goal for both is different from a normal bar of soap because the lather needs to stay dense with small bubbles. I have been brushing my teeth with this soap for about 6 months now. It works exceptionally well for both use-cases. I even bought a super nice German made shaving razor to use with it. I am also quite pleased with how the razor works. I tested both without using the conditioning oil and with, and the conditioning oil really helps a ton as a pre-shave. As for using it for brushing teeth with, surprisingly nice. Literally the cleanest I've ever felt my mouth to be, and took off the hardened plaque around the base of some teeth. After a few months noticed my teeth starting to whiten up too.

I think the 'soap tastes bad" comes from two sources, for natural soap if its too old and going bad it will also start to taste bad. Synthetic soap (detergents) probably tastes like shit and shouldn't be used for that to begin with.

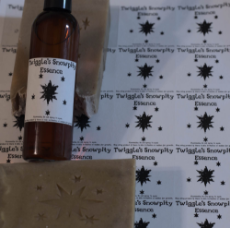

Third image is a high resolution picture of the snowpity essence bottles on my website https://snowpity.shop

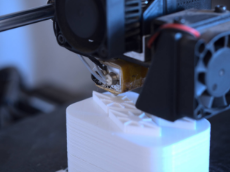

4th image is of the shitty 3D printer I have making the stamp used for rarity soap bars. I did not build any draft angle into the stamps, though they would probably benefit from it. Maybe one day I'll make some proper stamps out of steel.

Last image is when I got around to rendering my own tallow for soap making. I was rather upset with the quality of lard I was purchasing from my local store. After doing some testing with some tallow I rendered early on, I decided the best thing was to find a good local source and go through the extra effort rendering tallow brings. Bought a couple of big pots and rendered around 8 gallons of tallow.

Making soap with home-rendered tallow is a little different, but overall I am pleased with the results. Not to mention the soap is made with that much more local products. Remember: The more local something is made, the better off everyone is locally, strengthening the community.

Stuff not pictured:

Mare Fair! Early on in the development of mare fair's schedule and venue, I was asked to make soap for all of their sponsor badges. I've been vibrating about mare fair ever since. Seriously, check it out >>>/mlpol/357936 →

I have been researching into setting up a soap milling system. Quite a bit more equipment is needed, and much more expensive to do, but should make the overall quality of soap a little better. Basically soap milling is the soap is made, poured, cured enough to shred, set aside to finish curing (for a week or two in my case), then the soap shreds are mixed with dye and fragrance and finally pressed back into a bar of soap.

Probably some more stuff I can't think of at the moment.

Seriously guys, I am glad for all of you. It's been fun staring the soap project off as just a shitpost and growing it into... well... a much higher quality shitpost that can be sold as a product.

Stay clean everyone, hopefully I'll get to meet some of you guys at mare fair.

[Read more] First I'd like to thank the anons here who helped come up with the soap label ideas by the power of shitposting and autism.

>>6575 Mix jojoba oil and castor oil together. This is the best thing to use on skin or hair to keep it soft, supple, and pliable. This is what I sell as "Aloe and Lotus Conditioning Oil", there really isn't anything better for skin use than both of those oils. They don't mix though, so you will need to shake it before every use.

>>6195 Thanks, I really like it, even though I haven't even seen that episode (stopped watching around mid-season 7)

>>6191 Basically I took a break from a lot of things. Still kept doing the soap stuff but cut back on a lot of other things and relaxed a bit over the last month.

Hoooo boy lots of updates to cover.

Lets start with dye, where I left off at.

All of the soap bars require a little bit of white dye, generally one or two teaspoons for a batch. Sometimes less and sometimes more (more for Rarity, less for Celestia) because after I changed around temps and how much water I use, the natural color of the soap is pinkish, fair skin tone sort of color.

I mix/blend the dye with a portion of the oil in a blender first, and add that to the mixing bowl just before adding the lye to start the soap making process.

Changed the amount of water:lye ratio to roughly 1.75:1 at 2:1 there is just enough water that the soap just starts to leave a white ashy top surface. While harmless, it does mess with color and presentation a bit. Soda ash forms from the sodium hydroxide reacting with the carbon dioxide in the atmosphere. I think I mentioned this in previous posts and how it forms depends on how much water you use and what temp the soap is made at.

Alright, some pictures to highlight the progress, starting with the first image

Designed and welded up a soap cutter to use with my steel soap mold. At first I used some wire, but that didn't work very well. After thinking about it for a bit, decided to use heavy duty fishing line. This has worked quite well. Overall quite pleased with it.

Shaving soap! Also toothbrush soap to brush teeth with. The design goal for both is different from a normal bar of soap because the lather needs to stay dense with small bubbles. I have been brushing my teeth with this soap for about 6 months now. It works exceptionally well for both use-cases. I even bought a super nice German made shaving razor to use with it. I am also quite pleased with how the razor works. I tested both without using the conditioning oil and with, and the conditioning oil really helps a ton as a pre-shave. As for using it for brushing teeth with, surprisingly nice. Literally the cleanest I've ever felt my mouth to be, and took off the hardened plaque around the base of some teeth. After a few months noticed my teeth starting to whiten up too.

I think the 'soap tastes bad" comes from two sources, for natural soap if its too old and going bad it will also start to taste bad. Synthetic soap (detergents) probably tastes like shit and shouldn't be used for that to begin with.

Third image is a high resolution picture of the snowpity essence bottles on my website https://snowpity.shop

4th image is of the shitty 3D printer I have making the stamp used for rarity soap bars. I did not build any draft angle into the stamps, though they would probably benefit from it. Maybe one day I'll make some proper stamps out of steel.

Last image is when I got around to rendering my own tallow for soap making. I was rather upset with the quality of lard I was purchasing from my local store. After doing some testing with some tallow I rendered early on, I decided the best thing was to find a good local source and go through the extra effort rendering tallow brings. Bought a couple of big pots and rendered around 8 gallons of tallow.

Making soap with home-rendered tallow is a little different, but overall I am pleased with the results. Not to mention the soap is made with that much more local products. Remember: The more local something is made, the better off everyone is locally, strengthening the community.

Stuff not pictured:

Mare Fair! Early on in the development of mare fair's schedule and venue, I was asked to make soap for all of their sponsor badges. I've been vibrating about mare fair ever since. Seriously, check it out >>>/mlpol/357936 →

I have been researching into setting up a soap milling system. Quite a bit more equipment is needed, and much more expensive to do, but should make the overall quality of soap a little better. Basically soap milling is the soap is made, poured, cured enough to shred, set aside to finish curing (for a week or two in my case), then the soap shreds are mixed with dye and fragrance and finally pressed back into a bar of soap.

Probably some more stuff I can't think of at the moment.

Seriously guys, I am glad for all of you. It's been fun staring the soap project off as just a shitpost and growing it into... well... a much higher quality shitpost that can be sold as a product.

Stay clean everyone, hopefully I'll get to meet some of you guys at mare fair.

>>6726

>implying I was gone

>implyra

was making random posts on occasion here, just never really enough time to sit down and make a proper update on the soap making project.

Glad to finally get around to it.

I do enjoy the posts everyone else has been doing too

>implying I was gone

>implyra

was making random posts on occasion here, just never really enough time to sit down and make a proper update on the soap making project.

Glad to finally get around to it.

I do enjoy the posts everyone else has been doing too

1684723658.mp4 (1.3 MB, Resolution:1280x720 Length:00:00:08, Essence Pony - You can call them smells but I call them Essence!.mp4) [play once] [loop]

>>6725

ty u 4 returning, soapone. I haven't read the thread yet, but you're really missing out on the essence mare. Total cute mare. Her and Stellar Flare (Milf of the Season). Sad.

ty u 4 returning, soapone. I haven't read the thread yet, but you're really missing out on the essence mare. Total cute mare. Her and Stellar Flare (Milf of the Season). Sad.

>>6725

Wow, nice work. I look forward to trying some out.

Sadly I'm too poor to go to mare fair this year, but perhaps if things go well I'll be able to sneak it in next year.

Wow, nice work. I look forward to trying some out.

Sadly I'm too poor to go to mare fair this year, but perhaps if things go well I'll be able to sneak it in next year.

>>6725

Can't wait to see you at marefair, still trying to decide whether to use the Mimosa soap or keep it for the memory can I have two?

Can't wait to see you at marefair, still trying to decide whether to use the Mimosa soap or keep it for the memory can I have two?

Whew, mare fair was so much fun! Was so busy preparing for Mare Fair I didn't have time for much else. Got to meet a few of you though, which was fun.

Also have a bit of a soap update from a bit before the convention.

In this attached picture from right to left: the purple dye I (was) using, the same purple dye inside a little test dish with lye in it, soap with that dye added, soap with the same dye and more blue added, and finally a bar of soap with different purple dye added with (a bit too much) black.

I have two different kinds of purple dyes, and up until that last bar of soap in the image, I was using both purples and some white that should have gotten really close to Twilight Sparkle's succulent purple coat. I just could not figure out why the color was coming out all wrong but all the other soaps I make were mostly correct in color.

Turns out, as seen in the little test dish in the picture, the sodium hydroxide (lye) reacts with that darker purple color I have to give a tan/brown sort of color. Meh.

The other purple I have is a fair bight lighter in color, so I'll mix it with a tiny amount of black. In the picture, I did as much with the very last bar of soap, but added a little too much black, but at least its visibly purple.

From now on I'll only be using the lighter color purple. It looks closer to glimmer by its self, and definitely don't want that, so a little bit of black will be added to get the good Twiggle color.

I also have some other soap stuff I've never done before but wanted to for /mlp/ secret santa, but haven't been able to until very recently. I'll post pictures once my assigned santee posts pictures after they get it.

Speaking of... is there going to be a secret santa event for mlpol?

[Read more] Also have a bit of a soap update from a bit before the convention.

In this attached picture from right to left: the purple dye I (was) using, the same purple dye inside a little test dish with lye in it, soap with that dye added, soap with the same dye and more blue added, and finally a bar of soap with different purple dye added with (a bit too much) black.

I have two different kinds of purple dyes, and up until that last bar of soap in the image, I was using both purples and some white that should have gotten really close to Twilight Sparkle's succulent purple coat. I just could not figure out why the color was coming out all wrong but all the other soaps I make were mostly correct in color.

Turns out, as seen in the little test dish in the picture, the sodium hydroxide (lye) reacts with that darker purple color I have to give a tan/brown sort of color. Meh.

The other purple I have is a fair bight lighter in color, so I'll mix it with a tiny amount of black. In the picture, I did as much with the very last bar of soap, but added a little too much black, but at least its visibly purple.

From now on I'll only be using the lighter color purple. It looks closer to glimmer by its self, and definitely don't want that, so a little bit of black will be added to get the good Twiggle color.

I also have some other soap stuff I've never done before but wanted to for /mlp/ secret santa, but haven't been able to until very recently. I'll post pictures once my assigned santee posts pictures after they get it.

Speaking of... is there going to be a secret santa event for mlpol?

>>7103

Has this happened before on /mlpol/? I figure it wouldn't be too hard to coordinate unless I'm severely underestimating the user base here, hmm...

Has this happened before on /mlpol/? I figure it wouldn't be too hard to coordinate unless I'm severely underestimating the user base here, hmm...

>>7135

I don't think it has, and somebody trusted enough would have to be the one collecting doxes to pair people up otherwise most skizos won't even bother.

I don't think it has, and somebody trusted enough would have to be the one collecting doxes to pair people up otherwise most skizos won't even bother.

>>7137

I think people would trust you, hell ya already got the dox of everyone who's ordered soap from you

I think people would trust you, hell ya already got the dox of everyone who's ordered soap from you

shorter shitpost this time

https://sweethaven-soaps-and-sundry.storenvy.com/products/36734801-morning-in-the-library-bar

Got one of their bars at harmonycon and while I was trying to search for their web page I had their soap sitting on my computer desk. In the short amount of time its been sitting here, I got a bit of a headache just from the shitty fragrance they use for their soap.

I'll probably use it once, maybe twice, but I expect to break out in rashes from the shitty fragrance.

Apparently they use a pre-mix of oils sold to soap makers because they can't brain hard enough to figure it out themselves.

They only list a couple of bars of soap on that page but they had a lot more, including bath bombs, at their harmonycon table. They were also one of the only ones wearing a mask other than the furfags.

Their soap is also freaking tiny, less than half the size of a "I Can't Believe It's Not..." soap bar.

At least the colors are interesting with swirls and stuff I guess. Mica is expensive to use for soap dye, but it does offer more control over color and is generally more vibrant.

Their soap bar was somewhat squishy, which means either they did not let it cure long enough to let the water evaporate, or they didn't use enough lye.

Gave them a bar of "I Can't Believe It's Not Appul" soap, maybe they will drop their soap making thing out of shame.

I know I sound like I'm out there to destroy everyone who tries to make pone-themed soap, but its really not the case. There was a lot of dialog while I was talking with them and was never rude about it. They were just starting and were trying their best.

They mentioned they wanted to make some proper old-school soap by collecting ashes and extracting the lye and selling that at a renaissance fair. Good luck Sweethaven Soaps and Sundries, its a lot of extra work on top of everything else.

[Read more] https://sweethaven-soaps-and-sundry.storenvy.com/products/36734801-morning-in-the-library-bar

Got one of their bars at harmonycon and while I was trying to search for their web page I had their soap sitting on my computer desk. In the short amount of time its been sitting here, I got a bit of a headache just from the shitty fragrance they use for their soap.

I'll probably use it once, maybe twice, but I expect to break out in rashes from the shitty fragrance.

Apparently they use a pre-mix of oils sold to soap makers because they can't brain hard enough to figure it out themselves.

They only list a couple of bars of soap on that page but they had a lot more, including bath bombs, at their harmonycon table. They were also one of the only ones wearing a mask other than the furfags.

Their soap is also freaking tiny, less than half the size of a "I Can't Believe It's Not..." soap bar.

At least the colors are interesting with swirls and stuff I guess. Mica is expensive to use for soap dye, but it does offer more control over color and is generally more vibrant.

Their soap bar was somewhat squishy, which means either they did not let it cure long enough to let the water evaporate, or they didn't use enough lye.

Gave them a bar of "I Can't Believe It's Not Appul" soap, maybe they will drop their soap making thing out of shame.

I know I sound like I'm out there to destroy everyone who tries to make pone-themed soap, but its really not the case. There was a lot of dialog while I was talking with them and was never rude about it. They were just starting and were trying their best.

They mentioned they wanted to make some proper old-school soap by collecting ashes and extracting the lye and selling that at a renaissance fair. Good luck Sweethaven Soaps and Sundries, its a lot of extra work on top of everything else.

>>7366

Damn dude you didn't have to rip the newbie a new one like that. They just need to improve their product, not get browbeaten into giving up their hobby.

Damn dude you didn't have to rip the newbie a new one like that. They just need to improve their product, not get browbeaten into giving up their hobby.

[Reply] [Last 50 Posts] [Last 100 Posts] [Last 200 Posts]

You are viewing older replies. Click [View All] or [Last n Posts] to vew latest posts.

Clicking update will load all posts posted after last post on this page.

Post pagination: [Prev] [1-50] [51-100] [101-103] [Next] [Live (last 50 replies)]

103 replies | 62 files | 30 UUIDs | Page 3

[Add to Thread Watcher]

Ex: Type :littlepip: to add Littlepip

Ex: Type :littlepip: to add Littlepip  Ex: Type :eqg-rarity: to add EqG Rarity

Ex: Type :eqg-rarity: to add EqG Rarity