148 replies | 63 files | 59 UUIDs | Page 1

tl;dr: post shit about how to machine or manufacture shit here. Being able to make shit makes you more of a man with bigger balls.

Lets start on the political side of manufacturing with a USA centric theme.

Once upon a time, USA was the best. It was the best because it allowed anyone to build anything they wanted and purchase anything they wanted. After all, things you own are tools, and tools are needed to survive. Why should the government put any kind of restrictions on tools needed to survive?

Well, over the years, that is exactly what they did, because the more difficult it is for you to survive with less (or incorrect) tools. The more difficult of a time you have surviving, and the less you can do something about the government.

The greatest of all these is the ability to make more tools or better tools. In the modern vernacular, this is called machining, manufacturing, fabricating, and a lot of others that are more industry specific. I suppose the second greatest ability is to be able to protect such things, but that is outside the scope of this shitpost.

Why is the ability to build [tools] important? Because it lets you, the invisible hand, be able to swiftly deal with governments (problems) how you see fit in ways that nobody can anticipate. Why do you think policies being pushed through has been moving businesses over seas? The government does not want you to know how to make shit. Workers unions have not been nice either, but as near as I can tell that is the result of a different symptom (greed). In either case, bureaucracy is a hindrance to market (you: the invisible hand’s) agility.

I could rant about all the stupid shit in various markets that result in what I already said, but instead I’d rather focus on shit that will make a better life for you. In general, focusing on the use of lathe and mill work. Lets start with the stupid basics.

Example of CNC lathe in use:

[YouTube] CNC Lathe - Turning a Chess Rook by Glacern Machine Tools![]() [Embed]

[Embed]Example of CNC mill in use:

[YouTube] 5-Axis CNC Machined V8 Engine Block!![]() [Embed]

[Embed]Admittedly both examples are with machines that are a bit fancier than what might be typically found, but that does not change anything other than how many times a part is handled before it is finished.

Using a lathe is called turning a part. Using a mill is called milling a part. Turning and milling parts, along with some of the more exotic methods of cutting material (such as waterjet or EDM or centerless grinding machines), is called machining.

While I don’t follow the religion of safety (the reason why ppl are so worried about C-19 to begin with), there are certain things shat should be done or not done to keep all your limbs attached to your body. Things like leaving the chuck key in and walking away. Or wearing a long sleeve shirt and reaching around the quill of the mill while its on. Don’t be a dumbass and instead use that head attached to that white neck of yours.

What I’d like to do from time to time is post in here about various machining and manufacturing practices, tips, tricks, and methodology at large.

Remember though, its not about me, its about giving you the knowledge and tools to become richer yourself. If you have a question or something related, go ahead and post it.

I can't wait until I move out of an apartment and can partake in stuff like this. I recently heard about 'lost PLA casting'. It seems like a pretty economic alternative to milling metal. There's quite a few videos of people using the technique with very cheap apparatus. The guy in this video takes it a bit further.

[YouTube] Lost PLA Casting complete guide - everything you need to know - technique equipment & more by VOGMAN![]() [Embed]

[Embed]

While most of the stuff I make are made out of various different kinds of metals, I do find myself making parts out of various different kinds of plastics from time-to-time. Some of which can be quite special in design and use-case.

All plastics require very sharp tools. I do not suggest using the same tools used for cutting steels. Typically aluminum cutting tools will work very well on plastics too. Just make sure they are basically brand new.

https://www.maritool.com/product_info.php?products_id=17838http://www.robertsonprecision.com/KITS_AND_PRODUCT_INFORMATIONThe most commonly machined plastics are going to be acetal (delrin is teh brand name), UHMW, PTFE (teflon), nylon, and acrylic (plexiglass)

There are going to be variations on all of these too. For special use-cases (such as a higher performance plastic bushing) graphite or other things are sometimes added. In the end, acetal and UHMW are the most common. Acetal because its harder and chips nicely while machining, and UHMW because of price and how slick the surface is; thus used as plastic bushings pretty much everywhere.

All of those plastics, and probably a billion more that they keep designing for special edge-use-cases, are very easy to machine with properly sharp (nearly razor-edge) cutting tools.

The only concern you need to have with these materials is making sure you are not melting it from spinning too fast and feeding too slow. Typically I don't use coolant when turning or milling these parts, but they also tend to swell quite a bit from the heat of cutting. Before making the final cut, make sure the part is relatively cool, and more often then not it will be fine.

/* *** */

Does anyone have a request for the next topic? At the moment I'm just kinda throwing shit out there, but will also consider requested topics.

If not I'll probably make communist autists ree about USA standard vs the communist metric measuring systems for my next topic, and what they mean when making real parts in the real world.

Srsly tho, inject requests.

Do automatic shotguns made from 3d printed parts and assorted pipes you can pick up at any stire work?

>>4036Also what's wrong with the "communist metric" system? Is feet and inches superior to centimeters and meters or vice versa?

>>4039It's what burgers are used to, and any change would be seen as bowing to foreign influence. Also going 80 miles per hour feels faster than going 130 kilometers per hour for some reason, and that's kind of what we're about.

>>4039>Is feet and inches superior to centimeters and meter or vice versa?metric is more straightforward for intellectuals who only work on paper and have to convert between scientific units all the time. imperial makes way more sense with physically human daily measurements whether at home or with physical labor. At least to me.

If I had my druthers we'd switch from decimal to the dozenal system because "3" factors into many more numbers than "5" does.

>>4041Dozenal system? Is that the one where 1A and 1B become numbers for 11 and 12?

>>4042no one really has a standard for the character for those numbers but yeah, 12 would be like 10 is

decimal: 01 02 03 04 05 06 07 08 09 10 11 12 13

dozenal: 01 02 03 04 05 06 07 08 09 0A 0B 10 11

>>4042>>4043>>4041Personally I feel like ponies would use octal, two sets of hooves with possible griffin influence/design.

>>4044>>4045>Personally I feel like ponies would use octal, two sets of hooves with possible griffin influence/design.Pinkie puts two and two and two together in the Cranky episode, which would seem to corroborate this based on an exponentiated interpretation thereof. There's no other reason to have three sets of legs, it's mathematically impossible.

>>4041In the most general sense, I agree is a frame of reference issue.

Most armchair warriors and elitists don't have a frame of reference to much of anything because they never make or do anything.

Lets say you go jogging all the time and run 2km down the road to a stop sign, turn around and run another 2km back home. This person has a very good frame of reference to how far or long a km, 2km, and 4km is. Now lets say our average armchair warrior who keeps in good enough shape to not have blood clots, gets on a treadmill and runs (walks) 1 km once a week. This person still has no frame of reference cause he didn't see how far he has gone. It's just a number with some amount of sweat to get it.

In general, converting between inches, feet, yards, miles, meters, and kilometers means almost nothing to people who have no frame of reference to some similar distance. If you tell me something is 36" long, I don't think of that number in inches, because that kind of distance, my frame of reference is in feet or a yard. Same thing with meters and kilometers. I'm pretty sure everyone else in the world is similar in nature with their own frame of reference. That is, taking whatever distance and mentally converting it to a number they can more readily understand. Same thing with any other unit of measure... weights like lbs, kg, slugs, grains... volumes like liters, cups, cubic inches, and ponies... and so on (yes, pony is a volume)

Having said all that, I believe inches has an edge in the machine shop that is not possible with the meter/cm/mm.

In the machine shop, almost everything on the communist measurement side is in millimeters. The millimeter, when broken down by factors of 10 further does not resolve nicely to the maximum tolerance that most machines and measuring tools can achieve.

Freedom units in the machine shop use the inch in literally everything made. When the inch is broken down its either in fractions (like a 3/16 drill) or by factors of 10 (decimal). Most of the time its factors of 10, such as 0.01 inches. The inch when broken down to the tightest tolerance achievable by both machine and measuring tools is 0.0001 inches. Very nice number to work with as apposed to 0.0025whateverthefuk mm

This is actually kind of important because most bearing press fits are ideally 0.0005" of interference fit, give or take a little depending on the size and type of bearing.

Sure machines can work with even tighter tolerances, and there are specialty manufacturing processes to make things in a much more precise way (like ballbearings, certain kinds of grinding processes...) but most things made are not with those specialty processes. Most things are made by machining in the standard lathe or mill.

Don't let the communists steal your frame of reference. They have none and wish to take everyone else's frame of reference. Why do you think schools are so fuk'd?

What if the solution is to move humanity away from large scale factories and towards smaller scale workshops in more areas?

Less pollution (probably?) and less govt/factory protection agency/trade union oversight over whatever you may decide to build

A website could be built where people can pay for and order a pack full of materials and items necessary to put together their own tools meaning any room in any house or any shed can become a workshop.

Plus if the zombie apocalypse ever happens people could make homemade 3d printed shotguns

>>4072>>4041Why does the difference in systems have to be political? They're just units of measurement. Just use whichever is more convenient.

>>4072>>4036>communistsHow is the metric system communist? Plenty of non-socialist countries use it.

There is literally nothing inherently political about it. It's not necessarily the best system, but calling it communist is nonsense.

>>4076>[leave] large scale factories and towards smaller scale workshops in more areas.Most machine shops, as near as I can tell, are fairly small with a relatively small team of people (or just one person) making parts for whatever job they can get. Typically to support other purpose-built factories or companies that only do one thing.

Machine shops are quite distinct from manufacturing facilities though, where there tends to be injection molding, big hammer forging machines in various foundries, and other various specialty manufacturing machines purpose-built for making one kind of product.

Consider the following video of valve building the steam controller:

[YouTube] Building the Steam Controller![]() [Embed]

[Embed]In general, the higher volume and larger scale something is, the cheaper and easier it is to make. Because of how difficult it is to develop the process and machine to make the process, few try to build their own to compete.

>>4078>>4077Lets start with the basics that I believe all of you already know. Socialism is the diet cola version of communism, and both are different forms of statism, among a lot of others out there.

Now lets consider who designed the metric system, who is pushing for it and why they are pushing for it's use world-wide. Carter? Complete communist one-world shill, along with everyone else pushing for it both before him and after him. That also includes my physics teacher when I was in college.

Go ask random people what they think of the metric system vs USA standard and why they think one system should be used over another; then ask what their political dispensation is.

The bottom line is that these people want to conform everyones lives to use the same everything because in their opinion, uniformity is power. The more you are like them the more power they (statists) have. Their goal is to drain out anything that makes anyone or any nation unique.

I personally have used both pretty extensively. Both in the machine shop as well as in the physics lab designing various systems including rocket engines and large rotating space stations (mostly for mental exercise, but reason does not matter).

Both systems work equally fine for everything. When designing or building something, you absolutely must keep track of the units involved regardless of the system used. All the steps are the same though for both measuring systems if you are doing it right.

If both work equally fine then why does it matter? Again, look at what I said earlier and who is shilling it the hardest and why.

fukem

>>4079>who designed the metric systemThe person who designed it has nothing to do with the inherent politics of the system of measurement.

Now, you could argue that multiple nations using the same system of measurement is globalist, but calling it communist/socialist is just spouting buzzwords.

>Their goal is to drain out anything that makes anyone or any nation unique.This is indeed the goal of globalists, however it's more likely that international businesses wanted to use the system that most people were using so that they wouldn't have to hire hundreds of translators. Developing countries used the metric system instead of inventing their own system because they wanted to be able to conveniently trade with the global economy.

America, on the other hand, was already such a large economy that we could reliably count on other countries to translate their measurements to ours because they want to trade with us, so there was no real need to switch from the British Imperial system.

It's just two forms of measurement. There is nothing inherently political about either system. People use what they use as a matter of convenience. Other countries use the metric system because they had no system of their own worth keeping; Americans use the British Imperial system because it's what we've always used. It's simple as that.

>>4079>If both work equally fine then why does it matter?It literally doesn't.

People only complain about the U.S. because it forces them to learn two systems if they want to trade and/or cooperate with the United States, which they don't have to do for other countries: it's just inconvenient for them, so they complain. Even then, those people don't actually give a fuck. People figured out decades ago that trying to get the united states to change all if its traffick signs at once and teach children different units was a lost cause, and that's why the serious propaganda concerning stopped decades ago.

>>4079>That also includes my physics teacher when I was in college.I learned the metric system for Chemistry. A lot of American scientists use the metric system, because they periodically have to swap notes with non-Americans and read research that was published in other countries. It's not a political thing, and it's definitely not inherently socialist. It's for that reason that people who work in the fields of science and engineering learn the system, even if they go back to using the British Imperial system at home.

The people who probably care the most about the metric system are probably capitalist corporations, because it makes it easier for them to trade on a global level.

How do you learn engineering and programming languages without paying jews anything?

>>4146You go to the programming website and read the documentation or watch videos.

>>4146And write the programs and hope by bashing your head against the problem long enough with dedication you'll figure out the solutions.

Sometimes comparing what you wrote to what someone else wrote, and finding tips and tricks.

All depending on the cost of failure or down time.

>>4146See, that's an interesting question, and it can be rather simple depending on your goals. Programming for me was learned through books and lurking in programming related IRC channels. IRC is dying out currently, but matrix is filling in pretty well at about the same rate.

For engineering, it rather depends on the kind. Mechanical or similar, you are actually better off learning some physics and finding a machine shop to get an apprenticeship under (or maybe military machine shop apprentice, though military is full-cuck these days)

If certain things are still needed through a university or similar, hillsdale college is probably one of the few remaining Super-American Chad colleges out there.

https://www.hillsdale.edu/https://imprimis.hillsdale.edu/I've heard of other similar chad colleges out there that don't accept any government money, but it is not something I've looked for.

There are good open source textbooks too, for example this one on electrical engineering:

http://www.ibiblio.org/kuphaldt/electricCircuits/Might also be worth it to look into textbooks for the homeschooling crowd. I'm sure there is lots of good shit made that you (and I) could learn from.

One of my favorite things to do but never get the chance to these days is go in a large library and just start flipping through and reading technical books on just about anything.

[YouTube] Powerfist VS Doomfist DESTRUCTION![]() [Embed]>when your state bans guns but not PowerFists(tm)

[Embed]>when your state bans guns but not PowerFists(tm)

>>4190I watched that video... and enh. I've seen one or two other videos of stuff they've done and wasn't much of a fan. Most of the time people spending lots of money and effort for stuff like that are not making very interesting things.

It would not be any more difficult (either monetary or working hours) for a small group of people like that to design and build rocket engines and guidance systems for those rockets. You know, just in case a tank is rolling in your back lawn and needs to be stopped.

The neat thing about the attached video (LOSAT) is that its just a rocket with a tungsten nosecone. No high explosives at all, with about a maximum speed of about mach4, and completely obliterates all known (tank) armor, including reactive armor.

The rocket its self is decent size, but really not that big. To build something similar I think a lathe with a 6" through-bore would be sufficient with a C-axis package so things can be easily drilled radially to attach different components (nosecone, fins, fuel/oxidizer tanks...)

A brand new CNC lathe with C-axis and a 6" through-bore might cost something like $200,000-$400,000 without looking it up. Depending on make and model. Used would be much less than half that. And honestly an old beat up big lathe would be perfectly fine for that kind of application. Might find one for $40k plus shipping used.

I take that back, a brand new haas (American made CNC lathe) ST-45 has a 6.5" through-bore and with a C-axis package is "only" about $200,000. That does not include tooling, which might be another $10k-30k to get started with all-new tools, give or take.

Having said that, should be able to use a cheaper lathe with a smaller bore and instead just blank out each rocket body in the bandsaw to be maybe 3" longer and just use a long-bed lathe, ignoring the through-bore size. The main benefit of having a big bore lathe is that for a rocket, can easily make it longer to hold more propellant, instead of relying one a fixed-length lathe.

Buuuuuuuut... centerless grinders are a thing too, and would be more ideal to use. Centerless grind the whole bar of tube instead of turning blanks. I think ideally using a large-bore lathe with soft jaws, maybe even a 6-jaw chuck, and centerless grinding the seamless tube bars would be best.

As a side note

USA does not consider RAIL guns to be actual guns. Smoothbore too. Completely legal to own and use a 4.72" (120mm) smoothbore mounted gun without a license. The thing that requires a license is if there is explosives inside the projectile, like there typically is, with an impact fuse.

Euroland I think defines a gun by the amount of energy is dispensed. So I suppose a welding machine could be considered a gun...

(as far as I know)

>>4192>USA does not consider RAIL guns to be actual guns. >Smoothbore too. Completely legal to own and use a 4.72" (120mm) smoothbore mounted gun without a license.>The thing that requires a license is if there is explosives inside the projectile, like there typically is, with an impact fuse.Oh. Oh my. Oh me oh my.

If that is true

Ye olde blunderbuss or black powder designed rifle technically is fine.

You could hold a rocket in your hands, then use the exhaust to launch said thingy away.

>>4192What does the fourth axis on those things do?

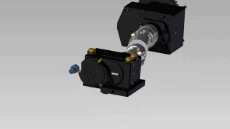

>>4194Standard lathes have two axis, Z and X, the third axis is the C axis (spindle orientation/rotation). An axis is defined as something inside the machine that can move either independently or in-time with any of the other axis. (without looking it up, pretty extra sure that's what it means)

For example, old CNC mills can sometimes be found as 2.5 axis. How is one of the axis a half axis? It can't move in-time with the other two axis even though its movement is separate from the other axis. The old bandit CNC mills were 2.5 axis. The X and Y axis (the bed) could move around in any direction at the same time, but not the Z (up and down), even though the Z could be programmed to move around, it just could not move at the same time with the bed.

The 4th axis in a lathe, which mind you is quite a rare thing to find for most used equipment, is the Y-axis... basically the whole turret with all the tools attached moves up and down. Useful for certain kinds of features, but enh... most of the time people skip the 4th axis unless they have lots of work for it and instead do any machining that would require it, in the mill instead.

Basically the Y-axis is only useful for cutting holes or slots off-center. Most lathe work, and even a lot of mill work is done from the center of the part

After those standard things found in a lathe, you can find more exotic lathes with a second spindle (subspindle) which may or may not have a C-axis, and a second turret. Some companies build special other kinds of tools in for cutting certain kinds of features really really quickly, or offer them as attachments you can add yourself.

The video is to demo one such device, which I believe is a company offering them as addon kits. I would generally consider something like that a half-axis, as you generally don't want the turret cutting at the same time the attachment is. And likely it comes with a 'safety feature' to even prevent that in some way (often a custom M-code that will throw an error if something moves in a way it shouldn't).

For a mill, there are the standard 3-axis, then 4th axis is the A-axis which moves a rotary table around in-time with all the other axis. The 5th axis is table tilt/swing. There are some 5-axis mills that instead of those things, the whole spindle assembly swings left/right and front/back for the 4th and 5th axis.

I have not had the chance to work with either a Y-axis lathe or a 5-axis mill. Done lots and lots of stuff with 4-axis mills and lathes with C-axis. Uh, not counting the years spent with the good ol' fashion manual lathes and manual mills, turning the cranks by hand.

Oh, the C-axis on a lathe always always comes with live tools, so you can drill or thread holes, or slot or form or various other things, in useful places in an easy way.

I think I answered the question somewhere in there.

>>4195Thank you.

I live with roommates for now, they're beginners slowly learning the truth from me. So I'd need a way to hide anything good I might build, preferably in plain sight. Or in parts stored in different drawers.

Got anything in mind? Also, what do you know about turning NERF toys into home defense items? I picked up a huge collection of nerf guns from a friend getting his shit together and moving on from collecting kids toys.

>>4196>hide anything good I might build, preferably in plain sight. Or in parts stored in different drawerslike, you have access to a lathe and a mill and want ideas for good things to build that can be hidden? I'm confused here.

>turning NERF toys into home defense itemsI've seen some of the videos. single shot nerf guns. Still need a chambered and rifled barrel to insert inside of them. Honestly just get black powder guns. They are cheap, the BATFE does not track them via serial number, classic history pieces, and very usable. Shipped right to your door. Black powder can be bought pretty easily, or even make your own relatively easily.

For a source of graphite to make black powder with, maybe go to an EDM shop and ask if they have any leftover chunks of graphite used for their EDM process that they throw away. Take the chunks and pulverize them to mix with potassium nitrate and a tiny bit of aluminum powder if you have it.

powdered graphite (carbon) can also be found in health food stores in the pharmacy. You know the classic hippy-like stores that are all about natural stuff. They sell it in powder so you can eat it and it somehow helps your stomach.

potassium nitrate can be bought as stump remover in most feed stores. The idea with stump remover is after cutting down a tree, drill a smallish hole in the middle of the stump and pour stump remover (potassium nitrate) in the hole. It will accelerate the rotting process and supposedly after about a year the stump is rotten enough to break up down to the dirt level without much effort.

Anyway, store bought stump remover has extra added stuff (red stuff in my experience) -- don't know what it is, but its not potassium nitrate. take the stump remover, dissolve in as little (pure/distilled) warm water as possible. Take the salty water and put in the refrigerator - salt crystals will form in the bottom of the container, this is pure potassium nitrate. Scoop the crystals out. Finish removing what you can by further chilling the water by putting ice in ziploc bags and putting in the container, try to get it as close to freezing as possible. More crystals will form, and scoop them out for later use.

It's kind of a lossy process, but really all refinement processes are lossy. Try weighing how much water you use and how much stump remover you use to figure out how much is lost. Post your finding here.

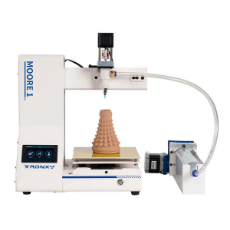

>>4199I know a guy with a lathe, mill, and 3D printer. I'm thinking of getting a 3D printer for myself. Ideas for good things to build that can be hidden would be great.

As for that chemistry refining powder stuff I don't think I could hide that from my roommates.

>>4202CNC or manual? the kinds of things you can easily make vary quite a bit between the two for both lathe and mill work.

Was at work a little later than than the normal amount of late because they asked me at the end of the day if I could get the thing done before leaving.

The annoying thing is that I started making a program for those parts in kind of a complicated way that lets the program be extendable and customizable for a large range of parts.

It is always a bad idea to try to rush CNC machine programming that includes variables, conditional statements, and loops to make a part. Chances are much higher to make a mistake, and mistakes can get really expensive really quickly.

Lets say for example you crash a high performance insert drill and ruin it. Drill is $600, another $100 for inserts... but you also need to include the amount of time lost the machine could have been running, and the cost to have somebody come in and re-align the turret. Things may get even more expensive if the linear bearings or ball screws were messed up (generally really difficult to mess those up, but I've seen it happen).

For a decent crash, its pretty easy to see the bill going in excess of $20k.

This is why I don't like being rushed when doing much of anything with machines. But today I still pushed making the program a bit. Caught all the initial-pass programming errors and somehow managed to get good speeds and feeds by pulling numbers out of my ass.

Everything came out perfect on the first run, surprising even myself a little. There had to be at least a dozen or two of "oh, probably about this fast" and "a radius of about this much, maybe", and "crap, I can't remember which way G02 and G03 works... lets just try this way".

Fortune seems to smile upon those with experience.

This is the kind of shit that you thought fit to share a fucking homeless guy for job hunting on a single-digit budget?? Yeah, lemme just put my ten thousand dollar lathe in my 5x5 storage unit and program it with a raspberry pi with 1024mb of ram, that'll do just fucking swell.

I don't know why I talk to you fags. This board is worthless. I'm going to die destitute and alone and you fucks will be my only momentary help. Fuck everything.

>>4453kek - try reading it again. Small job shop machine shops exist all over the place and are pretty easy to find. Go to a random one found in the phone book (listed under Machine Shop in the yellow pages) and ask if you can work for them.

That's all I was suggesting to do.

>>4454I looked. Almost nothing but auto shops. The rest didn't even seem to exist when checked. And all of them need experience.

This board is a waste of time. I am going to beat off, pawn off everything in my storage unit, buy booze, and say the N word in a seedy sandwich joint. So long, thanks for all the fish.

>>4453do raspberry pis actually work for that or are you kidding

>>4457Do you live in California.

>>4458Not anymore. Gonna die in Fayettenam.

>>4453This isn't really a monetary advice thread.

>>4460OP thought machining would be a good route for my retarded potato nigger ass. Linked back here.

>>4462I can't pretend to know what you are going through anon, but we can work through it together. We might not always have the answers, but we do want to help.

>>4463blow it out your ass. I don't have the battery on this flip phone to spend pretending that anything on /ub/ has helped me with anything ever.

>>4464If you're who I think you are then I believe we've talked before and played PayDay 2, you're a nice guy - I know this for a fact. Not sure what's been up with you recently but I know it's rough shit; because last time we talked it was going really bad for you.

>>4465Check the /nomad/ thread if you really want to know. Trying to sell that steam account and PC, no takers. That is all I care to say. Good night.

>>4456Apparently linuxCNC works with the Raspberry Pi 4 -

http://linuxcnc.org/[YouTube] Linuxcnc on Rpi4 ethernet![]() [Embed]

[Embed]It works reasonably well because the Pi4 has an FPGA built in.

>>4076some other rando anons watching this thread but asking outside of here >What are the different kinds of shops out there?

I'm going to skip mechanic shops and other similar things, focusing on different kinds of manufacturing shops.

Lets take a glance at how resources move around for most steels, and other alloys.

Open pit mine -> steel mill/foundry -> distribution warehouse -> manufacturing shop -> [other warehouse likely, maybe two] -> retail store -> you

that's just a generic resource flow, there are many deviations to this of course, even at large scales, but it's still more or less what happens.

Steel mills take raw resources and work them over, adding precise amounts of each kind of material to mix into an alloy.

Foundry, or pattern shop, is used for casting large volumes of things, not uncommon to have 10% or sometimes higher rejection rate (because of voids in the castings). No material is wasted, it just gets melted back down and tried again.

Forge is where they take raw materials and either roll them (multiple times) or hammer them into a useful shape.

Heh, I had to do a little bit of internet searching on those, and even then it might not be quite right, as those are not things I interact with at all. It is the job of the metallurgist to make sure the correct alloy with the correct mechanical properties of the casting/forging/shaping thing it requires. Most of these things are defined standards such as cold rolled 1018 steel bars, a brake caliper casting used in cars, or a forged 7075 aluminum frame used for an AR15 rifle receiver.

Those kinds of shops tend to be really high volume, because it is easier to build that sort of equipment for higher volumes. Regardless of what kind of material processing is used, they all end up in a manufacturing shop somewhere, and in my hands to finish getting shaped into something useful.

In the machinist world, there are two main divisions: Job Shop and Production Shop.

There are deticated job shops or support job shops. Deticated job shops are pretty easy to find in the phone book listed under machine shops.

What I am calling support job shops are much more illusive. A large farm might have a lathe and a mill to fix farm equipment with. An electric motor repair company will have a small machine shop to repair bearing surfaces from the bearing that siezed up and melted. I've heard the navy will have a small machine shop on the larger ships to fix various things that might break. I've seen offset printer shops have their own machine shop to make various things to keep the high-volume printers going.

Production shops generally only make one kind of product, with small variations to that product. Sometimes a production shop will only utilize lathes and mills, but most of the time they use purpose-built equipment.

For example, machines making plastic sheets. These machines will likely be able to make plastic trash bags, but also able to make the thicker plastic sheets used to cover harvisted crops or as a sealed barrier under a house. Perhaps also the plastic wrap used for food as well as wrapping up pallets for shipping purposes.

The company making lighters, zippo, uses brass and a big stamping machine to form the outer shell of the lighter. I will bet that it is the same machine they used in WW2 making the same lighers.

Some production shops will only be making one kind of product, but with normal CNC mills or CNC lathes. For example a company selling pipelines to oil companies. They will have CNC lathes set up for turning the end and threading the pipe. Their entire shop will be optimized for offloading steel pipe from various trucks, storage, and moving the pipes into lathes.

[YouTube] Building the Steam Controller![]() [Embed]

[Embed] - building the steam controller

Here you can see a typical modern production shop with lots of fancy deticated equipment designed and set up to make one product.

Most of the work I do is prototype these days, or sometimes making difficult-to-machine parts in a small production run on the order of hundreds or less.

Consider AirCrete(s) (foam plus cement, sometimes with additives).

Highly insulative.

There's also styrofoam additive making it like sticky sand.

The fiber mesh and other stuff gives alot of structural strength.

>My little workshop tour>A very well equipped shop https://www.youtube.com/watch?v=3DK5-psBKfo [Embed]

In this picture are two different kinds of edge-finders. One of them is $20 made by Brown&sharp in USA, the other $500 made by Haimer in Germany. Guess which one is more accurate?

The Brown&Sharp is more accurate by at least a factor of 5.

Why even bother having the Haimer? It can reach in places the other can not, is accurate enough most of the time, and is a bit faster to use.

Disclaimer: I do not own the Haimer and occasionally make fun of the guy who does. I personally never use it because I perfer to be as precise as possible.

Tradeoffs like this is exceptionally common in the machine shop. In order to make money, a really good understanding of tools and machines are needed. Sadly, this knowledge is dwindling because politics hate manufacturing, machining practices are not being pushed in college, and people don't like to work.

I'm sorry for not posting here more.

If anyone deserves this knowledge of power its you guys.

Being able to create a physical Aryanne in a time of need is a powerful beacon of hope to what remains of the free world.

THE FOLLOWING IS PROFESSIONAL LUMBER ADVICE. LUMBER AND THE RELEVANT EQUIPMENT CAN KILL YOU VERY EASILY. TAKE EVERY AVAILABLE SAFETY PRECAUTION

The first step in pulp product production - what you common folk call lumber - is to cut the goddamn tree down. Youre gonna want a sufficiently sized chainsaw as relates to the size of the tree. Plenty of ppl on youtube have done good 'how-to fall trees' and 'types of cuts' videos, check them out.

You will need: Safety glasses, hardhat, chainsaw chaps, ear plugs, gloves, boots, sufficient clothing (jeans and tshirt).

For simplicity's sake, 9/10 times youre gonna want to make a horizontal cut 1/2 of the way into the tree, and another cut below and at an angle (about 30deg) to meet with the horizontal cut. Knock that wedge out.

Next, align the saw with the 1st cut, on the other side of the tree. Slowly, make that cut WATCHING VERY CAREFULLY and pulling the saw away (in a pinch, leave it) and yourself as the tree begins to fall. If it stalls, you can continue, but err on the side of caution; its easier to make another, deeper cut than it is to not realize its falling and something bad happens. Safety first.

>Pic related, was unsafe one time. We'll get to that in the joinery portion

Next step is easy, clean the branches off with the chainsaw. Recommended to have a limbing saw in addition to the falling saw.

Next step - after a bit of hauling (I leave that to you) - brings us to the mill. Milling is simple, the machine makes a single horizontal cut at the level you set. When stripping the outside of a tree, youll want to cut off 1/2"-1" chunks; these boards are considered scrap, but later on Ill describe how to make cool shit with.

After about 3-4 cuts, rotate the log 90deg on the mill, to repeat the process on all 4 sides. Your objective is to square off or 'Cant' (industry term) the log, heretofore referred to AS a cant.

Once you've done that, its time to cut boards off.

When cutting boards, theres some important details that are industry standard.

>Ex: A 2x6 board purchased from hom4 depot will only be 1.75"×3.5". This is because in the industrial process, the starting board was 2"x6", however the finishing process (drying, planing, eased edges, etc) takes off a bit of material, leaving 1.75"x5.5".

So, if you're going for a box-store size board, dont sweat it, just go with basic measurements.

HOWEVER, you may come across clients who want a finished 2" thick tabletop, for example. As a rule of thumb, add 1/2" to whatever dimension needs refinement. That gives you 1/4" 'breathing/working' room to account for moisture loss during the drying process, as well as during the actual surfacing (planing, sanding, and finish).

Next, once you have your boards cut, youll want some paint and some joinery tape.

Joinery tape is those metal strips with a bunch of prongs on one side, intended to be nailed across 2 boards jointed together. You see them in barn rafters alot.

Thats not what we're using it for.

First, paint the ends of the board with latex, or some other form of thick, moisture resistent paint. You can get the fancy stuff designed exclusively for the ends of boards/logs, but meh. Regardless, paint the ends.

Next, tack the joinery tape on both sides of the boards.

When lumber dries, it tends to lose moisture MUCH faster through the ends, which causes cracks and splits in the ends of the board. This can be corrected for, but it means losing wood volume, and you dont want that since you probably have several hours invested in the wood already.

The paint acts as a moisture barrier, forcing the moisture through the sides of the board (rather than the ends), and the tape prevents the wood from splitting as it dries. It sounds like a pain in the ass (it is, ngl) but it produces a superior quality board, without need to fill or glue back together.

Next step brings us to drying. You can dry boards outside in a process of several months, OR you can rig a kiln.

Personally, I recommend getting an 8x20 storage container, painting the bitch black, putting it in Texas, and mounting a fresnel lens (big-ass magnifying glass) to the top. On a good hot day, that should get 'er up to ~140 degrees. With this setup, you can dry boards in a few weeks rather than a few months. Youll want a dehumidifier also, as the moisture will saturate the air and then return to the wood as the kiln cools at night.

Ta da, youve got wood. Stay tuned, we gonna make some shit.

>>4689Bruh, did you actually lose the tip of your index?

Fuck

>>4690Theres only 2 types of woodworkers. Those who have lost digits, and those who havent lost digits

yet.

Seriously, I havent been able to properly check 'em for ages.

Weird, I havent done anything to get a new ID. IDFK

>>4689One of the things I've always wondered is where you can find the most local wood mill.

I have known several people with their own, but I can't imagine trying to find one after moving to a new place.

>that scar on the little fingergnarly

>>4694Band-saw mills (portable or fixed) are much more common these days, and alot of millers/sawyers have listings on faceberg. Also, check with any local tree services, I guarantee they know someone.

Whether milling or contracting (fully 60% of my income is from private subcontracting)

the most valuable thing you can have is a reputation for being a solid, hard workerEspecially as things get more hairy with vaccines and mandates and shit, if you're out in the country you're within a 10 mile radius of prolly 5 ranches that need hard workers. And, when you do good work, they'll tell their friends.

Dont wanna do subcontracting?

Neither do I, but you better if you wanna have the social connections you're gonna need to survive when supply chains shut down, and infrastructure begins to collapse.

Just finished a 3-day job where my cut was 1.5k for 1400' of 4-strand barb wire. Dont worry, Ill get back to playing with wood, this iz just some theory/philosophy and a bit of strategy.

Cuz rn, especially with everyone scared of covid, its near impossible to make a living with a private mill. But, if you can establish yourself as a hard worker and contractor - ideally with periodic fine wood products for sale - who also happens to have a mill, your reputation will precede you. Especially if you're the guy who's missing a finger tip. Literally, they call me pointless.

Heres a pic of a recently cut post-oak stump. You can see the initial cut on the right, with the drop-cut on the left (drop-cut being the cut that causes the tree to fall). The thin spiky section is what holds the log until it hits the ground and separates from the stump. You want this, as it helps to guide the log during the fall. NEVER CUT TREES DOWN IN HIGH WIND. Ask OSHA how many fatalities they have from people thinking that a breeze wont affect the dropping of trees.

Also, nrver drop trees without a spotter. By that I mean, never drop trees without someone watching everything going on, ready and waiting to grab ur ass bybthe collar and drag you away from getting killed.

This is NOT hyperbole. It is astonishingly easy to get yourself killed while felling logs. When felling trees, if the log grts hung up and wont fall cuz of another tree, they call those 'widow-makers'. That too isnt hyperbole. Please be safe.

>>4696>Correction for angleThe wedge cut is on the north side, the drop cut is on the south side.

Ill have milling pics soon, but I got a project before I can implement my new setup. But thats okay, I got this much done, and its only lunchtime!

>>4720>second picThat's a big mixer anon...

>>4721I sure as HELL ain't mixing 5 yards o concrete by hand!

>>4722Probably not a good idea...

>>4723The pad is 12'x18', ~5.5-6" thich, with 5" deep footings along the perimeter. The metal structure is Cattle fencing (cuz rebar is prohibitively expensive rn, as well as more rust-susceptible) running across the bottom, with scrap pieces running vertical along the footings.

This is to accommodate my mill, which is ~5'x16', leaving an area to remove, trim and paint the board-ends before running them into the kiln. The problem with portable mills is levelling (and relevelling) the bastards on soft ground, especially after heavy rainfall. NOW I can set it and forget it, and more than double our production, without cutting into contract work.

One thing I DIDNT appreciate when starting out is just how much organization, planning, configuring, reconfiguring, and development has gone into an already established company. But thats ok, by the time the weather starts to warm back up (its Texas, so early Feb) we will be running solid, with opportunities to further develop the business property in between jobs and such.

>>4724>The problem with portable mills is levelling (and relevelling) the bastards on soft ground, especially after heavy rainfall.I see now, you got me thinking on the logistics behind this

How often do you have to move the mills?

>>4725It fluctuates. This time of year, maybe 2x a month; spring thru fall, anywhere from 6-12+ times a month, depending on clientele. It usually takes about 1/2 hour on soft, uneven, or off-level ground. The pad wont help for that, but it will allow us to get the mill set back up at our place in about 10 minutes with no need to check the level after rainfall. Plus, we can extend our hours of operation because the work area will be stable, safe, and clear of hazards and obstructions

cutting a finger off amps one's safety-consciousness. Moreover, once we get a tin roof over it and a few light ballasts, we can run after dark, allowing us to concentrate as many operations in a day as possible, maximizing production and allowing us to get more ambitious with the number/intemsity of the jobs we seek and take on.

Its all super meta and boring details, but

Im excited AF with the possibilities.

>pic relatedthe motherfucker who took my finger down

>This is brilliant!... The beauty of #engineering & continuous improvementhttps://twitter.com/TechAmazing/status/1486481324638720000 [Embed]

>>4726Shoot!, i don't even know how i missed your post.

>The pad wont help for that, but it will allow us to get the mill set back up at our place in about 10 minutes with no need to check the level after rainfallRight!, now i get it, i know nothing about this, so i was kind of confused before.

>Its all super meta and boring detailsNah, atleast it's pretty interesting to me, i am always curious about how the industry operates in different capacities.

>pic related the motherfucker who took my finger downI did saw the other posts, fuck...

A few things about milling.

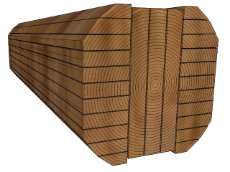

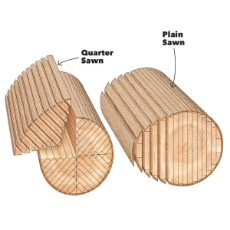

In order to maximize the usable wood from a log, you'll want to start with 4 full-length cuts as pictured (the flat parts). This will partially cant the log, making it more manageable for later setup. This method takes longer than just slabbing it out (routine horizontal cuts), but the result is a better product.

After flattening all sides a bit, you'll want to cut as thick of a chunk off the top and bottom, and set them aside. For me, thats about 6.5-7" (without scraping) thick, which later will be put back on and cut into quarter-sawn boards. Ill go into detail about quarter-sawing later, just know 'its better'. The vertical oriented boards in pic 1 are quarter-sawn (except thr corners,

Once you have the rounded chunks off, its just a matter of slabbing up the middle, determined by the purpose.

In pic 2, we are cutting to make an epoxy counter-top with a matching island.

Note: we NEED 3 pieces, but we cut 5.

Always cut more than you need. The most retarded-ass circumstances can foul an entire board, and theres no sense cutting into another log for one board of you can help it, especially given the amount of drying time that is necessary

In short, its always better to have more wood than you need, rather than less.

When milling, you'll want one of those painter blades that look like a giant spatula, for cleaning the sawdust off. Pretty much all portable bandsaw mills use water to cool and lubricate the blade (a dab of soap helps too), so the cut face will always be wet and caked with sawdust. Scrape that shit off, all of it, cuz that dust will mold and stain the surface of the wood. Its not the end of the world of it does, but to restore the surface you'll need to sand more surface than you may want to. The boards in #2 are cut to 1.75", to have a finished thickness of - quoting - 'anywhere between 1 and 1.5". We should only have to take a 1/4" off to finish it but I can always make the board thinner later, and unless no one likes you, there is no such thing as a board stretcher. So, erring on the side of caution is generally advisable, until you're at a point that calls for precise/finish cuts.

The type of sawing/board refers to the grain pattern of the board. If the board has vertical grain through its thickness, its quarter-sawn. If the grain is diagonal, its called rift or half sawn, and if the grain is horizontal through the thickness, its straight sawn.

Quarter-sawn is the strongest, most durable, and least susceptible to warping, flexing, expanding, etc. when wet. Quarter-sawn is the exclusive choice for doors, frames, flooring, etc for these and other reasons.

Half sawn wood is stronger than straight, but is.more susceptible to warping as it dries and is usually reserved for posts, furniture legs (especially when turning them on a lathe) and other pieces that are likely load-bearing in some capacity.

Lastly, there's straight cut. Basically, every construction grade board you will find at a lumber store (unless specially order) will be straight sawn.

Straight sawn boards are strongest along the length of the board, which is why theyre reserved almost exclusively for construction.

The bottom board from the cant will always be irregular. This is because as thickness is removed, the board expresses its elasticity more, and unless the mill has a completely flat deck (Ive never seen one), the ends will hang off the risers. The board pictured on the mill is 1.75" in the middle, but 2"+ on the sides. This can be brought to uniformity but it can be tricky, so until the job is done, consider that an 'emergency use' board, and plan so you dont have to use it.

Also, I do NOT recommend hydraulic/automatic mills. While they have dofferent settings for different wood types, and they unquestionably go faster than hand/crank-powered mills, there is ALOT of variance that can go into one tree vs. another.

Texas pine is ALOT denser than Pacific Nw pine, because of the increased sun and high levels of moisture. They take longer to dry, and theyre alot heavier and stronger than PacNw. Theyre also harder to cut through. Leaving the machine drive to a hydraulic.motor and a computer MIGHT get more cuts done in a shorter amount of time BUT it wears out the blades MUCH faster, causing curve in the cuts (very very bad) or outright failure of the blade. The machine cant compensate for knots either, whereas you can see and FEEL the density of the wood when its hand-driven.

Me? Id rather take 30 seconds/cut and get a superior product than 15/cut and have to reject boards because they have inconsistent thickness cuz I was in too much of a hurry. Take your time and go slow.

Well shit, wasnt expecting rain today. Oh well.

Look at that woodgrain! Isnt it gorgeous?

The darker parts are called spalting. Literally, it is the onset of decay in the wood. Its tricky to catch the wood before its really started to decay, but while spalting will downgrade (decrease commercial value) production lumber, its desirable (ideal, even) to woodworkers and crafters.

I like you, niggas, but I've been doing very similar shit for over a decade and never lost a finger.

>>5161Its

ninjas, and get back to me when you've been at it over 20 years

>>5162or mayhaps he refers to the machining stuff.

>>5161The hell does an accident have to do with anything? Plenty of accidents happen with lots of craftsmen of all varieties. Your statement means nothing in regards to both skill and relevance to the topic. Maybe show your own work to make a skill argument and contribute to the subject matter. Surely with that extra appendage and decade of experience you have some work to present.

>>5162Apologies, based oldfag.

>>5164>Plenty of accidents happen with lots of craftsmen of all varieties.Indeed, they do. I've always put safety above all else and I'm lucky enough to be self-employed, so it's not like some faggot can coerce me into doing dumb shit that ends in mutilation.

>Maybe show your own work to make a skill argument and contribute to the subject matter. I'm afraid you guys will have the Russians airstrike my position. I've seen what weaponized autism can do. There's no way to post my metal work without doxxing myself and posting my wood wouldn't do much unless you really like gazing at other men's wood.

Maybe I'll have something to contribute if I can get a milling machine or new welder, but there's nothing I could teach you that an old pro couldn't do better.

I don't want someone with the resources and autism calling my customers to tell them what a spectacular Nazi horsefucker I am.

>>5165>I've always put safety above all else and I'm lucky enough to be self-employed, so it's not like some faggot can coerce me into doing dumb shit that ends in mutilation.Thank you, I appreciate the qualification. It will come as no surprise that exhaustion, frustration, and working with an unusually small piece that contributed to the removal, but the main issue was that I wanted to be DONE for the day, and I let my safety practices lapse for a moment.

While Im clarifying, I should point out that a jointer doesnt cut digits off, it

shaves them away away, layer by layer. And yet, even though the finger only made 'contact' for about .1 seconds, that was enough for about 30 rotations. It was gone before I even registered the occurrence. A mere fraction of a second, and Ill never be able to game the same again (my left-trigger/right-strafe finger is too short nao ~_~)

Fun fact, the experience felt like a mix of smacking the finger REALLY hard (but just impact, no pain) and then losing all circulation. Ngl, it was way milder than I had anticipated.

But to you and yours

>I've always put safety above all elseGood. Keep it that way, it only takes one time. Silver lining? Theres a saying around the shop now: "Thats the kind of thinking that cost me/ninjas a finger."

>>5165>I don't want someone with the resources and autism calling my customers to tell them what a spectacular Nazi horsefucker I am.the ones that stay will be much more loyal. Maybe you should tell/show them to weed out the shitlords you don't want to do business with anyway.

>There's no way to post my metal work without doxxing myself That's why I don't post stuff that I've made over the years. Most of the stuff I make is pretty specialized and can likely be traced to two or three sources (including me) just based on the part and what it's used for.

>>4552>aircreteJust mix eggs into it. Or if you want to be /vx/, blood. Either rot quickly and release gas, foaming it up.

Doesn't do well for mortar, though, because it ruins repairability - mortar should always be weaker than the bricks it's binding so in a pinch you can remove and replace it, and the super-strong cement mortars you can get with eggs and pozzolana won't be removable.

>>4691That's pretty accurate. There always comes the time when you think you're knowledgeable and experienced, get careless, don't follow the safety procedures, and boom! At least it's an opportunity to literally write the rules in blood.

>>5165>unless you really like gazing at other men's woodIve been known

no homo to admire other men's wood. Purely a professional gesture tho

>I don't want someone with the resources and autism calling my customers to tell them what a spectacular Nazi horsefucker I amAh, we differ in that regard, Im quite looking forward to someone trying. To qualify that, I have enough business that I can be choosy about who I do work for, and all of my current business contracts have already listened to more than one rant about the jews. Technically, my clients are as much friends as they are customers, so its not a traditionally 'professional' arrangement, but yeah. Come at me doxfags.

>>5266>bloodFukking based

Hey /ub/ ever had to clear a large plot of land in a short time? Dont have a brush hog?

Put a metal-cutting cirxular sawblade and put it on a weed eater. This thing is beefy enough to cut through up to 4" stumps in seconds. Quit trying the weed eater, you'll just break your line on sticks and shit.

When you do, it is advised that you hold the foregrip as normal, but with your operating hand, pull the weed eater so that it is in constant contact with the full length of your right arm. Then, lock the device against your hip.

This will give you an incredible amount of control, enough to compensate for any time the device kicks out so u dont cut ur toes off. heaven knows Ive already cut enough off already.

In this configuration, one can cut down rough, uneven, stick ridden, unkempt mess at just below the speed of standard weed eating.

>>6039Those roads weren't subjected to cars, let alone lorries. Of course old timey roads handle old timey challenges better.

>>6039>Without a single degreeThose roads were made by brilliant stonemasons and guildsmen who trained for their entire lives perfecting their crafts, many of which born into trade families with generations of familial experience.

It wasn't college, but it was an equivalent level of long-term training and education.

>>6081Where's that from?

>>4034You still alive, right?

>>6039Boomer meme false equivalency is top tier.

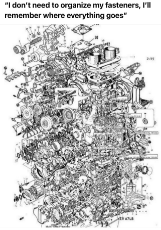

>>6081looks like the oil drain plug on a car engine... and either over tight, or somebody hit a rock or something, cracked the oil pan, and it finally broke with the next oil change. the oil drain plug is the lowest part, so plausible enough that it wasn't just over-tightened

Sorry guys I haven't been posting nearly as much as I'd like to. There are tons of machining things I'd like to cover, such as the different kinds of taps there are (plug, spiral point, hand, spiral flute, forming...), typical CNC lathe and mill commands, uncommon CNC machine programming practices, some pictures of some trashed tools from big mistakes that other people made that I collected and how to avoid doing such things yourself, and probably a lot more.

There just isn't enough time in the day

Thank you ninjas for helping the thread out too, pretty sure everyone (including me) learned a bunch from your hard-wood posting. Everyone likes looking at it I think.

This is based mastery, no doubt about it.

>>6103>and either over tight, or somebody hit a rock or something, cracked the oil pan, and it finally broke with the next oil changeNo way. That's the aftermath of a catastrophic engine failure and someone must've thought it would be funny to take a picture with the wrench on the drain plug. A grade 4.8 bolt would've broken off well before the oil pan.

>>6112>That's the aftermath of a catastrophic engine failureIt might very well be that. The edges look like the result of an internal explosion tearing apart the pan in a thousand pieces.

>>6103I'ma be perfectly honest with you. I left the site about a month ago, and am only here for the moment out of morbid curiosity.

If you're too busy to post, you're doing it right. Mlpol could have been alot of things, but it will never realize them because of the incompetence and duplicity of staff.

Wanna never amount to anything in life? Mlpol is a good place to make that happen. Nothing against ponies, but this place has been trash for a very long time, and I hope (you) specifically grow out of it. Peace.

[YouTube] Narcissists are users (continued)![]() [Embed]

[Embed]

>>6124>I left the site about a month agoWell then, have well wishes and fortune your way, frien.

>>6124>NinjasThat is utter bitterness. Take your time fren, (we) are waiting for your return.

Signed: Poner.

>>6124I really hope you change your mind. In all honesty, pointless endeavors do exist within this site. But I think there's plenty to post and do. Just don't feel pressured to post if you don't have time to spare, or wanna spend it in something else.

At any rate, wish you luck in whatever you are up to. And if you truly must leave, take the pony with you.

>>6129>And if you truly must leave, take the pony with you.Absolutely THIS.

>>6155Boomer may mays. Post cars instead.

>>6156That goes in the WEBM thread.

>Catastrophic failure at an aluminum extrusion line. Looks like an overpressure event and the oil itself (over a drop ceiling no less) open a portal to a demon dimension…

- One second from the hydraulic failure to start of fire.

- ~9 seconds after the fire started he returned to the desk.

- ~5 seconds after that the desk was splattered with molten aluminum and on fire.

- ~24 seconds after the fire started for everything to turn into a hellscape with collapsing ceiling tiles, which was ~13 seconds after he returned to the desk.

If that doesn’t tell you to GTFO instantly if a fire starts in an enclosed space, nothing will. Less than 30 seconds to get out before being burned alive.

>>4034>Being able to make shit makes you more of a man with bigger ballsI agree.

It's been a while, thought I'd drop in a post while waiting for the machine to finish making a part.

Economics this time, and general thoughts on what will end up happening in the manufacturing industry.

First off, as a reminder, manufacturing is the main measure for determining how healthy an economy is.

Right now in USA, there are tons of people losing thier jobs, but not in the manufacturing industry so much. This is mainly thanks to Trump from his first four years in office. Most of the people losing their job in this industry are either deadweight or unskilled button jockies that another (or newer) machine can do.

What this means is there is still a rather high demand for people willing to be good or exceptional as a machinist. This is before taking into account the military industrial complex getting all the free money to make weapons and kick-backs for Ukraine/Israel.

Machine shops are looking for experience because mistakes are very expensive. When interest and insurance was low, it didn't matter too much. Now consider that customers want their stuff delivered on time, shops are now very picky about who gets hired.

I believe this is very important because this is the first signs of major fat trimming for all industries.

The military industrial complex is putting a lot of unneeded pressure on an already undersized workforce pool. With the free-flowing fed money, who can resist such a cushy job? Top it off with people already saying "I'm just doing my job", the most important part of the economy is dying. Soon everyone will be working for the government because there isn't any money found anywhere else. As an aside, when I say 'for the government' I also include government contracts since the money comes frome the same place.

Soon, farmers won't be able to get replacement parts or equipment for planting and harvesting, to an extent. Even though farming is largely subsidized in USA, the government hates farmers because of how independent most are. Consider the Amish and how they are being forced by the FDA to do things a certain way these days.

Government response will be the same as it always has been since the gold standard was dropped: Print more money.

As near as I can tell, the only reason why things are not worse is because of how many guns are already in the hands of people that need them. Making more is trivial to any machinist, and is not a big deal to anyone else with some steel tube and a desire to defend themselves.

I am starting to feel vindicated from telling everone with an ear to get into either machining or farming.

>>4035You should check out electroplated PLA.

[YouTube] Electroplating 3D Prints | New Graphite Tutorial![]() [Embed]

[Embed] Yeah it's still plastic, but electroplating it can almost double the object's strength.

>>7509>>7510>>7511These are good stuff.

There used to be a 3d printer on the market that could 3d print using this stuff

https://en.m.wikipedia.org/wiki/Metal_clay you might be able to get away with repurosing a clay 3d printer. Glass clay also exists and is mostly used for jewlery. Metal and glass clay are also pretty easy to make

[YouTube] Homemade Bronze and/or Copper Metal Clay Recipe![]() [Embed]

[Embed]

>>7506>Nigger labourFuck no. The Jews may want to force whites into shit jobs. But there's no way am giving them what they want.

>>7516Either that or be a slave wage to make the jews even richer. Your choice.

>Implying you're not filling schlomo's pockets either way.

There's always a way to leech on.

>>7516If you don't get a job then you will never be able to afford your own land or equipment.

Turns out you can build a lot with recycled plastics.

https://www.preciousplastic.com/

How Civilization Ends. Civilizational and technological decline.

>If you’re looking for work, or to launch a business, you should probably look very hard at the opportunities in the machine shop area. Because it’s not just the car collectors who need metal parts machined.

Ownership of the means of production has never been easier.

>>7548Pic not related, a garage to keep them all in, and a house surrounding aforementioned garage.

>>7551Welcome to distributism

>>7547yep, this is exactly what I've been saying will happen for ~15 years, starting to see the effects of a very high shortage. Since the business/shop can't get skilled machinists customers complain about quality of work and stop going to that business. After a while there isn't any more of those specific kinds of businesses left. In this case its automotive machine shops.

Same issue where I live and a lack of good automotive machine shops. This is the net result of government handouts and subsidizing entire industries.

In other news, I made myself a couple of very nice steel tables from scratch. I plan on using these tables for some very cool things in the future, including but not limited to reloading bullets and investment casting metal ponies. I can't say when I'll get all the investment casting tools, but I'd like to have something to donate to mare fair charity auction.

>>7553forgot to mention,

https://www.lymanproducts.com/reloading/reloading-presses-kits/lyman-ultimate-reloading-system is the kit I got.

MidwayUSA has a really good deal on that kit right now for $550

https://www.midwayusa.com/product/1019119041?pid=509109 has everything needed except the reloading dies and shell holders. For reference, a similar reloading press from redding or RCBS cost $400 for just the press. The Lyman press is all made in USA, including the castings.

Take the stonemasonry pill

Behond! A 3D printer that can print clay for under $500!

Also

https://en.m.wikipedia.org/wiki/Metal_clay

So there I was in my little shop welding on some things and thinking about guns and ammo and how the state is buying almost all of it up, leaving nothing left for people reloading their own ammo.

Then I got to thinking "how could the state make it impossible for average people to own a gun legally?"

Well, they did already, sort of.

With the NFA tax, full auto and suppressors more than doubled the cost of the firearm when first implemented. It is only because they didn't scale the NFA tax with inflation that suppressors are fairly common these days.

But really, how could the government do it right now?

Let's back up a bit and see how a typical firearm system works. There is the cartridge which includes the primer, rifle powder, projectile, and casing. Then there is the rifle which is either bolt action or simi-auto.

The state (BATFE) knows that a low-ball ban would enrage most people, such as, declaring rifle powder a high explosive. I don't think that will happen.

What might happen though is switching to a completely different kind of ammo that doesn't use primers, and slowly shutting down primer manufacturers via OSHA regulations. There are only 3-4 companies in USA making primers.

Pretty much all commonly used munitions and firearms are designed by the military. If the military could buy firearms that are impossible to make on a lathe or mill then it's possible to slowly get rid of most civilian firearms. Almost all firearm companies rely on those juicy government contracts to supply the military and other government agencies with firearms and munitions. If the government suddenly switched to some sort of new design that some component was illegal to own, then I could see further divergence between government and normal people over the span of maybe 75 years or so.

>How The Amazingly Burly ‘Buffalo Bicycle’ is Changing The World[YouTube] How The Amazingly Burly ‘Buffalo Bicycle’ is Changing The World![]() [Embed] >17 minutes

[Embed] >17 minutesThis bike seems to be an engineer's wet dream. Does anyone know of other projects with the goal of "robust design and reparability with crude tools and limited supply lines"?

I know there are at least two laptop projects. The Framework laptop emphasizing reparability and customizability / upgradability, and another laptop with clear plastic and individual parts you can repair yourself and source from any store that does what Radio Shack used to do. This is different from just a housing for a Rasberry Pi or market equivalent.

This second laptop project costs a bit more than the first one, and I think it can't use windows.

>>8208>This second laptop project costs a bit more than the first one, and I think it can't use windows.I'm sure you mean the MNT Reform. That's good, as illiterate winblows niggers can't use it. The CPU is on a module, and so is swappable. There are different ARM modules available, and a new RISC-V module is being developed. I'm considering to get one someday. Let winniggers suffer eternally in jewtel/JMD x86 hell.

For the record, my smallest of kittens fixates on the spots I spray Ayanne snowpity

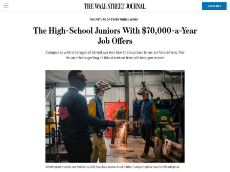

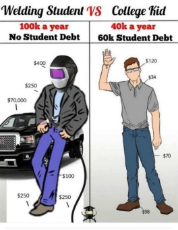

High school juniors with shop class trade skills like welding and plumbing are getting job offers for $70,000/year before they even graduate. No debt.

>>7601It might be worth learning about PCP air rifle design, rail/coil/gauss gun design, high power laser design, ect in addition to firearm designs. Never hold all your eggs in one basket.

https://thevirtualfoundry.com/Filament with metal, glass, or ceramic that can be sintered together. If you have a sintering kiln and a 3d printer you could make just about anything.

>>8649It isn't a one-off either. Numerous washes, and resprays, he digs his nose in Aryanne's luscious snowpity

One wonders what orgasms a cat0-tongue

<enough of that

>>8698Welders make good money.

>>8699Right? Skilled welders make 6 figures with a month or two on vacation

There was this guy Norm, who was a millwright at a treatment plant.

What is it about guys named "Norm" being absurdly skilled, btw? Never has the guy named Norm been anything but the expert.

Anyway, he worked as a millwright just to give himself an income for a while, before going BACK to work as an underwater bridge welder, making 600k/year

I think Trade Schools should get the same funding as universities. Skilled trades are just valuable, if not more so.

Ex: Type :littlepip: to add Littlepip

Ex: Type :littlepip: to add Littlepip  Ex: Type :eqg-rarity: to add EqG Rarity

Ex: Type :eqg-rarity: to add EqG Rarity