Walking home today, some fucker bumped into me and instantly started talking shit about aluminum being the best metal. I tried to remain calm and explain to him that iron was actually the best metal, but he wouldn't take a hint. He started throwing around words like "rust" and I lost it. Punched him right in his aluminum loving fuck face.

I hate aluminum so goddamn much. What are the political implications of aluminum loving normies going mainstream?

/mlpol/ - My Little Politics

Archived thread

>>369227

>rust

C'mon bigot, everybody knows that stainless steel is the best. That said if things are measured by corrosion resistance, then reality will give a sobering check. Most metals are meant to become dust again.

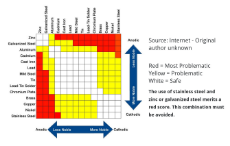

See "galvanic corrosion" for more info.

>rust

C'mon bigot, everybody knows that stainless steel is the best. That said if things are measured by corrosion resistance, then reality will give a sobering check. Most metals are meant to become dust again.

See "galvanic corrosion" for more info.

you are all niggers

the issue is both stainless steel and aluminum are soft, touch anything and it dents and is difficult to fix (IE cut out and weld)

The mane problem with cars is nobody makes a full-frame car anymore. makes for fixing things that much more difficult

the issue is both stainless steel and aluminum are soft, touch anything and it dents and is difficult to fix (IE cut out and weld)

The mane problem with cars is nobody makes a full-frame car anymore. makes for fixing things that much more difficult

>>369233

Nope. Nobody makes an stainless steel car because the material is too hard to work with, it lacks elasticity and may crack. On the other hoof, aluminum is avoided like the pest because it needs difficult welding and immediately caches corrosion in contact with other metals, as shown at >>369230

Nope. Nobody makes an stainless steel car because the material is too hard to work with, it lacks elasticity and may crack. On the other hoof, aluminum is avoided like the pest because it needs difficult welding and immediately caches corrosion in contact with other metals, as shown at >>369230

>>369234

>I know about stainless because I read about it

facehoof moment

seriously, stainless steel is soft and loves to get dented extremely easily. There are exotic stainless steels, such as used by kitchen knives, that are fairly tough.

I've worked with almost every kind of stainless steel. 304, 316, 416, 17-4, monel, and many others.

Just because a material is difficult to work with does not mean its not soft.

>I know about stainless because I read about it

facehoof moment

seriously, stainless steel is soft and loves to get dented extremely easily. There are exotic stainless steels, such as used by kitchen knives, that are fairly tough.

I've worked with almost every kind of stainless steel. 304, 316, 416, 17-4, monel, and many others.

Just because a material is difficult to work with does not mean its not soft.

>>369237

>Just because a material is difficult to work with does not mean its not soft.

Stainless steel is very hard. That's the very reason it cracks.

>I know about stainless because I read about it

Actually because many times I used a lathe to work with it. It is an extremely hard metal, so hard that tools have to be sharpened all the time.

>Just because a material is difficult to work with does not mean its not soft.

Stainless steel is very hard. That's the very reason it cracks.

>I know about stainless because I read about it

Actually because many times I used a lathe to work with it. It is an extremely hard metal, so hard that tools have to be sharpened all the time.

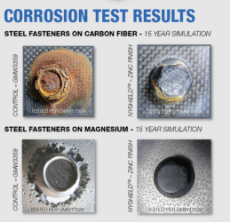

Same examples of galvanic corrosion (different metals making contact).

>>369240

lathe and mill. I've made probably hundreds of parts out of various different kinds of stainless steel over the 20 years I've been a machinist. Most of those parts I made the program and set up the machines myself.

The only stainless steel that isn't too soft that comes to mind is 17-4 and its one of the few magnetic ones.

The reason why you need to sharpen tools is because with monel, 304, 316, and similar, is that its so soft it gums up and does not want to leave the surface. Same issue with copper. At least copper (C110 grade) it does not complain too much when its squished around so extrusions are possible.

Believe me I know how picky most of the stainless steels are with what cutting tools are used.

lathe and mill. I've made probably hundreds of parts out of various different kinds of stainless steel over the 20 years I've been a machinist. Most of those parts I made the program and set up the machines myself.

The only stainless steel that isn't too soft that comes to mind is 17-4 and its one of the few magnetic ones.

The reason why you need to sharpen tools is because with monel, 304, 316, and similar, is that its so soft it gums up and does not want to leave the surface. Same issue with copper. At least copper (C110 grade) it does not complain too much when its squished around so extrusions are possible.

Believe me I know how picky most of the stainless steels are with what cutting tools are used.

<3 thread

>>369227

Isn't it a little suspicious that they've phased out tin foil and replaced it with aluminum foil, but they still call it tin foil?

Isn't it a little suspicious that they've phased out tin foil and replaced it with aluminum foil, but they still call it tin foil?

>>369256

>they've phased out tin foil and replaced it with aluminum foil

Tin is expensive and rare. Aluminum is cheap when produced en mass; so cheap that it's often thrown away, which makes it better as a disposable product.

>but they still call it tin foil

People don't change their language easily. It's the same reason why cheap flatware is often called "silverware" even though it's usually made of steel and not silver.

Aluminum foil you buy at the store isn't called "tin foil" anywhere on the box/roll; it's very clearly labeled as aluminum foil. People just colloquially call it "tin foil" because that's what they're used to.

>they've phased out tin foil and replaced it with aluminum foil

Tin is expensive and rare. Aluminum is cheap when produced en mass; so cheap that it's often thrown away, which makes it better as a disposable product.

>but they still call it tin foil

People don't change their language easily. It's the same reason why cheap flatware is often called "silverware" even though it's usually made of steel and not silver.

Aluminum foil you buy at the store isn't called "tin foil" anywhere on the box/roll; it's very clearly labeled as aluminum foil. People just colloquially call it "tin foil" because that's what they're used to.

>>369258

Tin used to be much more common for household things like baking tins (it's in the name) and for small furniture.

A few months ago while out and about it came to me that I haven't seen a tinsmith in the better part of thirty or so years when there used to be one every four or so miles.

The rate how how rapidly materials science has changed over the past fifty years has been amazing to see really, even if I'm vastly overlooking the horrible health effects that things like teflon and BPAs have caused.

Tin used to be much more common for household things like baking tins (it's in the name) and for small furniture.

A few months ago while out and about it came to me that I haven't seen a tinsmith in the better part of thirty or so years when there used to be one every four or so miles.

The rate how how rapidly materials science has changed over the past fifty years has been amazing to see really, even if I'm vastly overlooking the horrible health effects that things like teflon and BPAs have caused.

>>369395

Tin is widely used in electrical engineering, particularly in solder and to cost other metal parts to prevent corrosion; for that, I use it all the time. Tin has always been valuable because its low melting point made it easy to shape, which is what fueled the bronze age. In modern days, easily melted metals are valuable for precision work, such as electrical engineering.

>The rate how how rapidly materials science has changed over the past fifty years has been amazing to see really

Yeah, the later half of the 20th and early 21st century had a lot of technological advancements that drastically changed what materials people used, particularly in what what's considered valuable and what's considered disposable. Aluminum used to be more valuable than gold, before people figured out how to synthesize it from abundant oxides. Tin meanwhile is now considered too good to be thrown away in the form of soda cans. Material engineering is the king of engineering, since it dictates the limitations of every other form of engineering. The big explosion in computer science has all been fueled by finely cut quarts crystals.

Tin is widely used in electrical engineering, particularly in solder and to cost other metal parts to prevent corrosion; for that, I use it all the time. Tin has always been valuable because its low melting point made it easy to shape, which is what fueled the bronze age. In modern days, easily melted metals are valuable for precision work, such as electrical engineering.

>The rate how how rapidly materials science has changed over the past fifty years has been amazing to see really

Yeah, the later half of the 20th and early 21st century had a lot of technological advancements that drastically changed what materials people used, particularly in what what's considered valuable and what's considered disposable. Aluminum used to be more valuable than gold, before people figured out how to synthesize it from abundant oxides. Tin meanwhile is now considered too good to be thrown away in the form of soda cans. Material engineering is the king of engineering, since it dictates the limitations of every other form of engineering. The big explosion in computer science has all been fueled by finely cut quarts crystals.

14 replies | 10 files | 8 UUIDs | Archived

Ex: Type :littlepip: to add Littlepip

Ex: Type :littlepip: to add Littlepip  Ex: Type :eqg-rarity: to add EqG Rarity

Ex: Type :eqg-rarity: to add EqG Rarity