What 3D printer would be great for a man in the UK to get himself? I swear I'll only use this to make useful stuff and stupid funny stuff and never misuse it. The world of 3d printing is so vast and creative that buying one seems like a good investment.

Pics unrelated.

/ub/ - Überhengst

Becoming better

40 replies | 15 files | 8 UUIDs | Page 9

>>3184

>The world of 3d printing is so vast and creative that buying one seems like a good investment

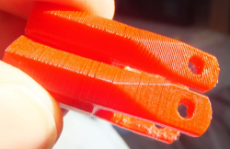

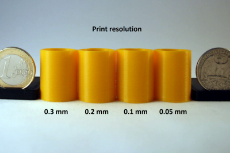

Before you hope on a 3D printing machine, get a printed part and analyze if it meets your expectations, be dimensional, be stiffness, be hardness, be elasticity.

Parts are printed with plastic at a very crude resolution. The higher the resolution, the higher the machine's price and the time to print.

>The world of 3d printing is so vast and creative that buying one seems like a good investment

Before you hope on a 3D printing machine, get a printed part and analyze if it meets your expectations, be dimensional, be stiffness, be hardness, be elasticity.

Parts are printed with plastic at a very crude resolution. The higher the resolution, the higher the machine's price and the time to print.

I could make cute poner toys and custom 3D printed guns that fire perfectly safe nerf darts. Could also build new parts when engineering and DIYing.

If you want to create mechanical kind models you might use FreeCAD, it's open source.

>Using FreeCAD for a 3D printing project

https://www.youtube.com/watch?v=Ls5MI3gSSlk

>Using FreeCAD for a 3D printing project

https://www.youtube.com/watch?v=Ls5MI3gSSlk

>>3187

Thank you, that program looks great!

My budget isn't super huge or anything but I don't want to buy something that's only cheap because it's crappy. Learned my lesson on that when I bought cheap crappy new pans and ended up having to replace them all when they got scratched up. Buy nice or buy twice.

My maximum budget is around 3000 british pounds, I saved a lot of money this year and last year.

Thank you, that program looks great!

My budget isn't super huge or anything but I don't want to buy something that's only cheap because it's crappy. Learned my lesson on that when I bought cheap crappy new pans and ended up having to replace them all when they got scratched up. Buy nice or buy twice.

My maximum budget is around 3000 british pounds, I saved a lot of money this year and last year.

>>3188

Checked.

Again, ANALYZE poner.

Investment means that you must have a return, otherwise is a failed bet.

Checked.

Again, ANALYZE poner.

Investment means that you must have a return, otherwise is a failed bet.

>>3189

That makes sense. Maybe I could make 3d printed and hand painted pony minifigures and sell them online?

That makes sense. Maybe I could make 3d printed and hand painted pony minifigures and sell them online?

>>3190

For organic shapes, 3D printing is the worst of the worst choice because of the resolution issue.

Seriously, 3D printing is mostly hype and restricted to make individual parts with mechanical shape, and because they are made of plastic, their IRL use is very limited.

For organic shapes, 3D printing is the worst of the worst choice because of the resolution issue.

Seriously, 3D printing is mostly hype and restricted to make individual parts with mechanical shape, and because they are made of plastic, their IRL use is very limited.

1608648164_1.jpg (49.7 KB, 600x600, 2d-dots-lines-and-shapes-presentation-qximz-throughout-2d-intended-for-2d-organic-shapes.jpeg)

1608648164_3.jpg (47.5 KB, 735x552, 8ac64c80f9d076b5fe76ac28af53d1a7--parametric-design-design-thinking.jpg)

1608648164_4.jpg (75.3 KB, 737x460, e4ffcb07adb1e444ec5d0b64c7deb085.jpg)

>>3199

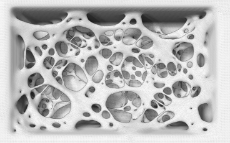

And this is after a lengthy calibration period of finding the optimal type of plastic, temperature, deck setting and material (protip: glass), etc. If one wants smooth, rounded surfaces (such as one might desire for a pone) expect to do alot of sanding, and possibly having to modify the model to allow for it.

Tl;dr dont expect to be able to sell these things, except by special order with loads of remanufacturing.

And this is after a lengthy calibration period of finding the optimal type of plastic, temperature, deck setting and material (protip: glass), etc. If one wants smooth, rounded surfaces (such as one might desire for a pone) expect to do alot of sanding, and possibly having to modify the model to allow for it.

Tl;dr dont expect to be able to sell these things, except by special order with loads of remanufacturing.

>>3203

Pay grade? In terms of skill or expensiveness?

I would love to make pony figures and maybe cool custom nerf guns.

Pay grade? In terms of skill or expensiveness?

I would love to make pony figures and maybe cool custom nerf guns.

>>3204

A CNC machine requires extensive experience and training to even operate at a basic level, let alone fabricate entirely. No offense, but with your experience you wouldnt even be hired to operate one.

A CNC machine requires extensive experience and training to even operate at a basic level, let alone fabricate entirely. No offense, but with your experience you wouldnt even be hired to operate one.

>>3209

There's a lot more to arts and crafts than just getting knick-knacks out of a 3D printer. Carpentry is a great hobby if you don't mind a bit of sawdust and it's a lot more versatile and cheaper than plastic. Welding is a nice way to make things out of scrap metal that you can find. Forging and/or metalworking is much more advanced but at that point you can make just about anything functional. Personally I see 3D printing as filling that gap for grips, decorations and other plastic parts that won't get stressed, because you can't really make them any other way. There are loads of Youtube videos about making cool stuff.

There's a lot more to arts and crafts than just getting knick-knacks out of a 3D printer. Carpentry is a great hobby if you don't mind a bit of sawdust and it's a lot more versatile and cheaper than plastic. Welding is a nice way to make things out of scrap metal that you can find. Forging and/or metalworking is much more advanced but at that point you can make just about anything functional. Personally I see 3D printing as filling that gap for grips, decorations and other plastic parts that won't get stressed, because you can't really make them any other way. There are loads of Youtube videos about making cool stuff.

>>3210

Given your track record for unrealistic expectations, it's worth considering. Also

>dream

Wake up

Given your track record for unrealistic expectations, it's worth considering. Also

>dream

Wake up

>>3211

>carpentry

>welding

These skills are always wanted, they don't require government permission or reporting and pay good $ bits.

And the most important thing, you will be the boss.

>carpentry

>welding

These skills are always wanted, they don't require government permission or reporting and pay good $ bits.

And the most important thing, you will be the boss.

>creative carpentry

>Making a Bladeless Wooden Fan - Scrapwood Challenge ep38

https://www.youtube.com/watch?v=a19OpQfwB2w

Check this out OP. I believe it has a good chance to inspire you.

>Making a Bladeless Wooden Fan - Scrapwood Challenge ep38

https://www.youtube.com/watch?v=a19OpQfwB2w

Check this out OP. I believe it has a good chance to inspire you.

>>3199

Could you make something like that and just use it for a mold for say resin casting or plastic injection molding?

Could you make something like that and just use it for a mold for say resin casting or plastic injection molding?

>>3199

Also is the layered surface really going to be a problem if the OP paints the figurine with a coat or two of paint?

Also is the layered surface really going to be a problem if the OP paints the figurine with a coat or two of paint?

My advice OP is get something cheap like an ender 3 or an anet 8 and get a good feel for 3d printing before going further.

>>3235

If I'm interpreting your question correctly, yes.

What you would want to do in that event is use the 3d printer to print a prototype. You would then use the prototype to make a silicone mold, and then use the silicone mold to resin cast an unrefined (not sanded and smoothed yet) resin product which COULD be marketed and sold after refinement.

>>3236

Another good question, and yes.

One or two coats of paint can smooth the layering of the product, however care should be given when selecting the correct paints.

>>3237

Can confirm, the ender is a good intro-intermediate level printer by which to acclimate to the medium, before making a more significant investment.

If I'm interpreting your question correctly, yes.

What you would want to do in that event is use the 3d printer to print a prototype. You would then use the prototype to make a silicone mold, and then use the silicone mold to resin cast an unrefined (not sanded and smoothed yet) resin product which COULD be marketed and sold after refinement.

>>3236

Another good question, and yes.

One or two coats of paint can smooth the layering of the product, however care should be given when selecting the correct paints.

>>3237

Can confirm, the ender is a good intro-intermediate level printer by which to acclimate to the medium, before making a more significant investment.

>>3240

>>3240

They can at least make something that you can use to make a mold for resin casting/injection molding. Also silicon molds and injection molds can be reusable and can produce more units faster than a 3d printer. So you can create many more products after you make your blanks. Also PLA is a pretty weak plastic resin casting and plastic injection molding will allow you to use stronger materials. Hell if you go with injection molding you could potentially use recycled plastic and eliminate material costs almost entirely.

>>3240

They can at least make something that you can use to make a mold for resin casting/injection molding. Also silicon molds and injection molds can be reusable and can produce more units faster than a 3d printer. So you can create many more products after you make your blanks. Also PLA is a pretty weak plastic resin casting and plastic injection molding will allow you to use stronger materials. Hell if you go with injection molding you could potentially use recycled plastic and eliminate material costs almost entirely.

>>3245

Sweet. How do I get started and where do I begin? Should I make Twilight Sparkle first or something simpler like a D20 20 sided dice?

Sweet. How do I get started and where do I begin? Should I make Twilight Sparkle first or something simpler like a D20 20 sided dice?

>>3252

And as a beginner should you really be worried about making a twilight sparkle? Do you even have a 3d printer? First things forst.

And as a beginner should you really be worried about making a twilight sparkle? Do you even have a 3d printer? First things forst.

>>3253

I don't have a 3d printer yet because I'm a complete newbie who's still not sure which one to buy. I expected there to be a handful of 3d printers out there but turns out there are shitloads of 3d printers out there.

I don't have a 3d printer yet because I'm a complete newbie who's still not sure which one to buy. I expected there to be a handful of 3d printers out there but turns out there are shitloads of 3d printers out there.

>>3250

You can print a twilight. It isn't particularly difficult. There is a bit of a learning curve in the beginning. If you get an ender 3 or anet A8 you will need to look up videos on leveling the platform. For getting prints to adhere to the platform I advise using painter's tape and a glue stick. For your slicing software I advise using cura as it has premade settings for most common 3d printers and if you are going to make a twilight the you are going to want to use support structures. Get your printing skills down then go on to resin casting or injection molding. I would advise resin casting first simply because it is a much easier process and doesn't require any machinery. Resin casting simply requires a blank, silicone to make the mold, and resin.

You can print a twilight. It isn't particularly difficult. There is a bit of a learning curve in the beginning. If you get an ender 3 or anet A8 you will need to look up videos on leveling the platform. For getting prints to adhere to the platform I advise using painter's tape and a glue stick. For your slicing software I advise using cura as it has premade settings for most common 3d printers and if you are going to make a twilight the you are going to want to use support structures. Get your printing skills down then go on to resin casting or injection molding. I would advise resin casting first simply because it is a much easier process and doesn't require any machinery. Resin casting simply requires a blank, silicone to make the mold, and resin.